|

| < Back | ||||||

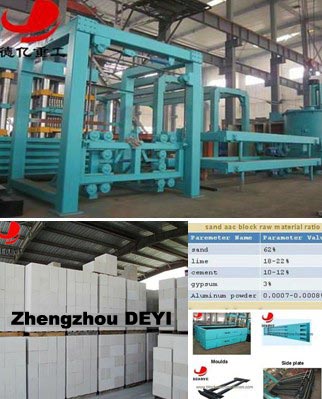

| Zhengzhou DEYI | ||||||

| About this company : We are a leading manufacturer of block making machinery in China with a history of 15 years. We have several kinds of AAC block production line to make different kinds of bricks/blocks with different capacities. Our AAC production line is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea. Our equipment is advanced, we use Aerial tumbling cutting units .PLC automatic ingredient, complete electric control system. It will help you improve efficiency and save cost. | ||||||

| Contact : fay lv , block machine | ||||||

| Headquarters : zhengzhou, zhengzhou, 450016, China | ||||||

| Phone : +860371-66162089, Fax : +860371-66162089 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

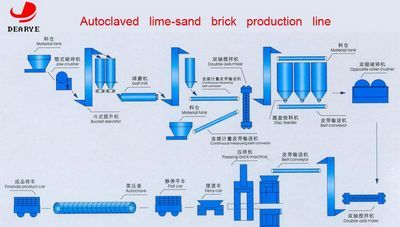

| automatic hydraulic brick machine DEYI brick machine Hello, everyone. We are zhengzhou DEYI heavy Industrial machinery manufacturing Co.,Ltd. As a leading manufacturer of brick machine in China with a history of 15 years.Our products own a good fame with the high quality and nice after sales services. We have several kinds of production lines to make different bricks/blocks, like autoclaved fly-ash brick production line, autoclaved lime-sand brick production line,hollow brick machine,blind holes brick machine, aac block machine production line ,baking-free brick production line. we are one of four leading manufacturers in china to produce automatic hydraulic brick machine. According the different capacity,we provide four type automatic hydrauli brick making machine for your reference:DY1250 block machine,DY1100 brick machine,DYS850 autoclaved brick machine,DYS430 baking-free brick machine. Full automatic hydraulic brick making machine is the host equipment of autoclaved lime-sand and fly ash brick prodcution line ,we can call them autoclaved brick making machine .

Welcome your visit for our full automaitc hydraulic brick machine hot selling in oversea. | ||||||

| > Add to cart | ||||||

| aac block machineaac machine DEYI aac machine block machine,aac production line,aac plant,aac block machine,aac machine,aac equipment,aac block production line, concrete block machine Feature: Our concrete block machine AAC production line is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea .Our equipment is advanced, we use Aerial tumbling cutting units . PLC automatic ingredient, complete electric control system . It will help you improve efficiency and save cost . The blocks raw material preparation and storage

| |||||

| > Add to cart | ||||||

| aac making production line DEYI aac machine We are zhengzhou DEYI heavy industry, we have many kinds of aac making production line for you with different capacity and raw materials, like fly ash aac making production line and sand aac making production line, the capacity from 50,000m3 to 400,000m3, welcome to visit us and our working aac making production line installed by us here. Do you know why will choose DEYI brand making production line ? AAC block is the new material for building, very popular. The processing of making production line : | |||||

| > Add to cart | ||||||

| aac plant from zhengzhou DEYI heavy DEYI aac plant Hot selling aac plant in China We are a leading manufacturer of block making machinery in China with a history of 15 years. We have several kinds of AAC block production line to make different kinds of bricks/blocks with different capacities. Our AAC plant production line is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea .Our equipment is advanced, we use Aerial tumbling cutting units .PLC automatic ingredient, complete electric control system will help you improve efficiency and save cost. The aac block machine production line process: Welcome to China and visit us for the aac plant.

| ||||||

| > Add to cart | ||||||

| aerated concrete production line from zhengzhou DEYI DEYI aac machine aerated concrete production line from zhengzhou DEYI We are a leading manufacturer of block making machinery in China with a history of 15 years. Our company designed aerated concrete production line project, has reached the leading level in the same domestic equipment, the production aerated concrete block compressivestrength can achieve 5.0 - a magnitude 7.5, shrinkage less than 0.8 mm/m, its high quality, light weight, penetration-proof quality good, sound insulation, heat insulation, heat preservation, seismic fine performance, the shape dimension precision, the damage rate is close to zero level. And the technological superior manufacture troop, complete quality guarantee system, ensure the product processing and assembling accuracy, so as to ensure the stability and reliability of our products. The aerated concrete/aac block machine production line process: If you want to set up aac block plant or aerated concrete block production line, welcome to visit our equipments for latest full automatic air turnover autoclaved aerated concrete production line and the worksite installed by us. Our aerated concrete production line is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea. Our equipment is advanced, we use Aerial tumbling cutting units /aac block cutting machine.PLC automatic ingredient, complete electric control system will help you improve efficiency and save cost .

| |||||

| > Add to cart | ||||||

| autoclaved aerated concrete block machine DEYI aac block machine autoclaved aerated concrete block machine We are a leading manufacturer of block making machinery in China with a history of 15 years. We have several kinds of AAC block production line to make different kinds of bricks/blocks with different capacities. like:fly ash aac block production line,sand aac block production line. Our autoclaved aerated concrete block machine is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea .Our equipment is advanced, , we use Aerial tumbling cutting units /aac block cutting machine.PLC automatic ingredient, complete electric control system will help you improve efficiency and save cost . The aac block machine production line process:

| ||||||

| > Add to cart | ||||||

autoclaved fly ash brick machine DEYI block machine

At the hot and humid temperature, A series of hydration products, such as hydration calcium silicate, calcium aluminates hydration, hydration aluminum calcium silicate and hydration sulfur aluminum acid calciumnstituent materials react with each other, these products all solids cemented together, forming strong overall structure, and make the products have strength of artificial stone.According to the technical conditions of the industry standard of the People's Republic of China: JC239-91 《 fly ash bricks》. The technological process of autoclaved fly ash bricks: 1.Lime, gypsum griding system | ||||||

| > Add to cart | ||||||

| best air turnover aac machine aac machine best air turnover aac machine Hello, dear sir. If you set up the aac plant, do you want to get the best quality air turnover aac machine and save cost? If you choose us, will design, installing and training the worker for you, and provide all the machines for your aac plant. Or say that we provide the turnkey aac plant and the save cost aac machine? Maybe you want to know, why will choose our air turnover aac machine? Then if you plant to expand your aac plant in the near future, about the land area, should be large in the first period, including the building, workshop, autoclaves area, raw material area and finished goods area. Our best air turnover aac machine has good quality and price for you, so research the new latest technology aac machine from us. Welcome your visit. If you have anything, please contact me.s | |||||

| > Add to cart | ||||||

| DEYI brand hydraulic brick machine DYS850 brick machine DEYI brand hydraulic brick machine Hello, everyone. We are zhengzhou DEYI heavy-as a leading manufacturing of hydraulic brick machine in China with 15 years, we also provide all the equipments for you brick making production line and aac block production line. DEYI brand hydraulic brick machine is new type and high technology brick machine, we use the double-sides pressure brick machine. DEYI brand hydraulic brick machine feather: Welcome to visit us. | |||||

| > Add to cart | ||||||

| DY1100 autoclaved brick machine DY1100 brick machine sell DY1100 autoclaved brick machine autoclaved brick making machine,Multi-function brick machine-DY1100 blockmachine

,multi-function hydralic block machineblock machine for autoclaved brick production line Fly ash autoclaved brick machine(lime-sand autoclaved brick making machine) Zhengzhou DEYI heavy Industry sell DY1100 autoclaved brick machine. DY1100 autoclaved brick machine/Block Machine we provide four type autoclaved brick machine :DY1250 brick making machine,DY1100 brick making machine,DYS850 brick making machine,DYS430 brick machine ,you can choose them according the capacity.We adopt double compression technology . | |||||

| > Add to cart | ||||||

| DYS850 brick machine for Tian jin On August, 12th, 2011, we sent our DYS850 brick production line to tian jin client, they will produce autoclaved fly ash brick.

| ||||||

| > Add to cart | ||||||

| DYS850 brick making machine automatic hydraulic brick making machine technical characteristics: 1.DYS850 automatic hydraulic brick making machine is a patented high-tech product developed by our company on the basis of digestion of the devices imported from America and German. 2.Hydraulic brick making machine adopts the four-column-three-beam prestressed tie rod cover structure and optimizing stress analysis of finite element, the structure of which is capable of bearing the tensile force above two thousand tons. 3.Our brick making machine applies the German Siemens PLG program control, man-machine interface and touching operation 4.The oil cylinder of our block machine are those imported with original packaging produced by German company and the cylinder body is casted with double-layer alloy , the inner surface of which is furbished with the heat treatment. 5.Applying the displacement transducer built in the oil cylinder of our block machine, it can exactly control the quantity of the loading material of the brick. The rate of products meeting standards is high with the error is only ±1mm. The bin level indicator installed in the feed tray can be automatically adjusted. 6.The hydraulic station of our brick making machine is the power supply for the whole hydraulic press. Our company applies the hydraulic originals which are produced by German hydraulic manufacturing company with original packing such as hydraulic pump, directional valves, etc..Furthermore, our company designs and applies the present most advanced international hydraulic control theory and valve transducers which realizes the prepressing , shaping pressing and pressure maintaining. 7.our automatic hydraulic brick making machine is automatic controlled by a computer from preparing the raw material dosage, mixing to product output, realizing full automatic operating, equipping the device for inputting and outputting data, realizes person-machine dialogue. It can display the process of operation dynamically, if there is a mechanical problem, it will shut down and alarm automatically, then show the position of the problem. There are many buttons on the window and submenus for mechanical actions from dosage material to output finished bricks that you only needs to choose from the menu. 8.The automatic block machine has double cement mortar preparing process to get multi-functions and can produce different kinds of bricks by replacing the moulds, such as varies kind of hollow bricks, manifold holes bricks, sidewalk color bricks and plant grass bricks, etc. | ||||||

| > Add to cart | ||||||

| fly ash brick making machine fly ash brick making machine Hello, dear friends, do you the fly ash brick making machine? Through the experiment, autoclaved fly ash brick frost resistance, corrosion resistance, compressive strength and many other performance is better than the solid clay bricks of artificial stone material.So the autoclaved lime sand brick can be directly instead of solid clay brick. fly ash brick raw material: If you want to set up fly ash brick making plant, please let me know, we provide the best fly ash brick making machine for you with good quality, price and servcie. We are zhengzhou DEYI heavy industry- the leader of brick making machine in China with 15 years. Our fly ash brick making machine feature: Welcome your visit. | |||||

| > Add to cart | ||||||

| High quality DYS430 brick machine brick machine High quality DYS430 brick machine DYS430 Brick Making Machine/Block Machine characteristics of DYS430 brick machine,fly ash autoclaved brick machine: 1.DYS430 automatic hydraulic brick making machine is a patented high-tech product developed by our company on the basis of digestion of the devices imported from America and German.

| |||||

| > Add to cart | ||||||

| sand aac plant DEYI aac plant Sand aac plant in China In these years, aac blocks become more and more popular for building.if you want to set up aac plant. We can provide all the full automatic equipments for aac block production line with good quality and price.According the different raw material,we can provide sand aac brick making machine/sand aac block machine and fly ash aac block production line. The sand aac plant,our AAC block production line is popular in home and oversea .Our equipment is advanced,we use Aerial tumbling cutting units .PLC automatic ingredient, complete electric control system. It will help you improve efficiency and save cost. Sand aac block raw material: The sand aac block machine production line/sand aac brick making machine process: | |||||

| > Add to cart | ||||||

| sell autoclaved lime sand brick prodcution line DY1100 lime-sand production line block machine produces the product intensity, can reach MU20, production technology level to be higher, low energy consumption, the products are widely used in building foundation and the internal and external wall.This autoclave brick production line saving land, and protect the ecological environment to have the important meaning. Autoclaved brick in our country has a certain scale of production, application has quite common. lime-sand production line We provide lime-sand production line Specifications of lime-sand production line: The autoclaved lime-sand brick :

| |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2025 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||