|

| < Back | ||||||

| Changsha Supmeter Technological Co., LTD. | ||||||

| About this company : Changsha Technological Co., Ltd., a member of China Weighing Instrument Association (CWIA), is a high-tech enterprise specializes in developing, customizing & producing industrial weighing, feeding, batching and packing indicators & controllers. Since the Company was established in 2004, it has been pursuing the cooperation principle of 'Customize Products for Clients, Build Strong Brands Together', pursuing the objective of 'Outstanding Quality, Continuous Improvement, Effective Services and Client Satisfaction' in mind, and insisting on the product direction of 'Accurate Weighing, Quick and Steady Control, Fitness for Industrial Environment, Standard Communication Interface', It has offered worldwide scale manufacturers with individualized technological services at pre-sale, during-sale and post-sale levels wholeheartedly. In just a few short years, 's products have been sold to over 100 worldwide scale manufacturers. Moreover, has built a long-time cooperation with several famous scale manufacturers, e.g. BOSCHE from Germany, on technical exchange, products customization and promotion. Through tracking and applying international advanced technology to meet clients’ demands, Supmter has elevated most of its products, esp. the BST series weighing & feeding & batching controllers for belt scale, to international advanced level. Depending on first-class technology, first-class quality, reasonable prices and best services, we'd like to establish win-win cooperation with worldwide scale manufacturers. | ||||||

| Contact : Lisa Ho, Foreign Trade Manager | ||||||

| Headquarters : No. 200, 2th Section, FuRong Middle, Changsha, HuNan, 410015, China | ||||||

| Phone : 86-731-85115100, Fax : 86-731-85158100 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

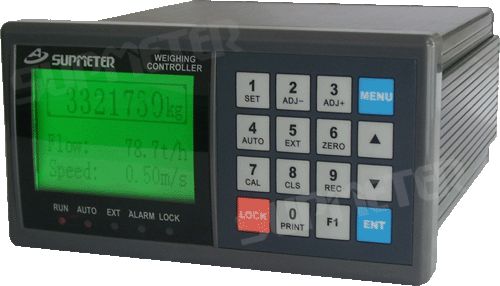

| Belt Scale Feeding Controller BST100-E01 BST100-E01 1. Suitable for Belt Feeder with Continuous Feeding Control.

2. 128×64 s LCD display screen with 7 background colors.

3. Can be set to Chinese or English display.

4. Menu&Shortcut mode operation with key tone.

5. High-precision ∑-△A/D conversion technology and broad-range speed pulse input circuit.

6. Max. Connection Quantity: 8 Loadcells (350Ω).

7. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and I/O testing functions available.

8. Auto Zero Tracking, Segmenting Span Correction, Speed Calibration and Belt Length Calibration functions available.

9. One optional ‘Flow Set Point’ analog signal input [AI: 4~20mA].

10. Max.3 definable ‘Flow/Control Current /…’ analog signal outputs [AO: 4~20mA].

11. Double-quick and steady feeding closed-loop control function available.

12. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

13. The feeder and belt scale can be started or stopped by DI&DO signals.

14. One ‘Totalized Weight High-speed Pulse’ output [

15. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

16. Support industry configuration software, e.g. iFix.

17. Weight Records per shift/day/month of a year can be queried and printed. | |||||

| > Add to cart | ||||||

| Belt Sacle Weighing Indicator BST100-D52 BST100-D52 1. Suitable for belt weighing scale.

2. 160×32 s LCD display screen with yellow-green background.

3. Can be set to Chinese or English display.

4. Menu&Shortcut mode operation with key tone.

5. High-precision ∑-△A/D conversion technology and broad-range speed pulse input circuit.

6. Max. Connection Quantity: 8 Loadcells (350Ω).

7. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and I/O testing functions available.

8. Auto Zero Tracking, Segmenting Span Correction, Speed Calibration and Belt Length Calibration functions available.

9. One optional Flow analog signal output [AO FROM COM1: 4~20mA].

10. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

11. Support industry configuration software, e.g. iFix.

12. Corrosion-proof, water-proof, dust-proof and shock-proof shell for model wall-mounting.

13. Weight records per shift/day/month of a year can be queried and printed. | |||||

| > Add to cart | ||||||

.gif) | Belt Scale Feeding Controller BST100-A11 BST100-A11 1. Suitable for Belt Feeder with Continuous Feeding Control (Flow Closed-loop Control).

2. 128×64 s LCD display screen with 7 background colors, 8 bits LED display for Model Panel-mounting.

3. Can be set to Chinese or English display.

4. Menu&Shortcut mode operation with key tone.

7. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and I/O testing functions available.

8. Auto Zero Tracking, Segmenting Span Correction, Speed Calibration and Belt Length Calibration functions available.

9. One optional ‘Flow Set Point’ analog signal input [AI: 4~20mA].

10. Max.3 definable ‘Flow/Control Current /…’ analog signal outputs [AO: 4~20mA].

11. Double-quick and steady feeding closed-loop control function available.

13. The feeder and belt scale can be started or stopped by DI&DO signals.

14. One ‘Totalized Weight High-speed Pulse’ output [

15. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

16. Support industry configuration software, e.g. iFix.

17. Weight Records per shift/day/month of a year can be queried and printed. | |||||

| > Add to cart | ||||||

| Belt Scale Feeding Controller BST100-A21 BST100-A21 1. Suitable for Belt Feeder with Continuous Feeding Control (Flow Closed-loop Control).

2. 128×64 s LCD display screen with 7 background colors, 8 bits LED display for Model Panel-mounting.

3. Can be set to Chinese or English display.

4. Menu&Shortcut mode operation with key tone.

7. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and I/O testing functions available.

8. Auto Zero Tracking, Segmenting Span Correction, Speed Calibration and Belt Length Calibration functions available.

9. One optional ‘Flow Set Point’ analog signal input [AI: 4~20mA].

10. Max.3 definable ‘Flow/Control Current /…’ analog signal outputs [AO: 4~20mA].

11. Double-quick and steady feeding closed-loop control function available.

13. The feeder and belt scale can be started or stopped by DI&DO signals.

14. One ‘Totalized Weight High-speed Pulse’ output [

15. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

16. Support industry configuration software, e.g. iFix.

17. Weight Records per shift/day/month of a year can be queried and printed. | |||||

| > Add to cart | ||||||

| Belt Scale Feeding Controller BST100-B11 BST100-B11 1. Suitable for Belt Feeder with Continuous Feeding Control.

2. 16 bits LED digit display screen with English display.

3. Menu&Shortcut mode operation with key tone.

4. High-precision ∑-△A/D conversion technology and broad-range speed pulse input circuit.

5. Max. Connection Quantity: 8 Loadcells (350Ω).

6. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and I/O testing functions available.

7. Auto Zero Tracking, Segmenting Span Correction, Speed Calibration and Belt Length Calibration functions available.

8. One optional ‘Flow Set Point’ analog signal input [AI: 4~20mA].

9. Max.3 definable ‘Flow/Control Current /…’ analog signal outputs [AO: 4~20mA].

10. Double-quick and steady feeding closed-loop control function available.

11. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

12. The feeder and belt scale can be started or stopped by DI&DO signals.

13. One ‘Totalized Weight High-speed Pulse’ output [

14. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

15. Support industry configuration software, e.g. iFix.

16. Weight Records per shift/day/month of a year can be queried and printed. | |||||

| > Add to cart | ||||||

| Belt Scale Feeding Controller BST100-B21 BST100-B21 1. Suitable for Belt Feeder with Continuous Feeding Control.

2. 16 bits LED digit display screen with English display.

3. Menu&Shortcut mode operation with key tone.

4. High-precision ∑-△A/D conversion technology and broad-range speed pulse input circuit.

5. Max. Connection Quantity: 8 Loadcells (350Ω).

6. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and I/O testing functions available.

7. Auto Zero Tracking, Segmenting Span Correction, Speed Calibration and Belt Length Calibration functions available.

8. One optional ‘Flow Set Point’ analog signal input [AI: 4~20mA].

9. Max.3 definable ‘Flow/Control Current /…’ analog signal outputs [AO: 4~20mA].

10. Double-quick and steady feeding closed-loop control function available.

11. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

12. The feeder and belt scale can be started or stopped by DI&DO signals.

13. One ‘Totalized Weight High-speed Pulse’ output [

14. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

15. Support industry configuration software, e.g. iFix.

16. Weight Records per shift/day/month of a year can be queried and printed. | |||||

| > Add to cart | ||||||

| Belt Scale Feeding Controller BST100-E11 BST100-E11 1. Suitable for Belt Feeder with Continuous Feeding Control.

2. 128×64 s LCD display screen with 7 background colors.

3. Can be set to Chinese or English display.

4. Menu&Shortcut mode operation with key tone.

5. High-precision ∑-△A/D conversion technology and broad-range speed pulse input circuit.

6. Max. Connection Quantity: 8 Loadcells (350Ω).

7. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and I/O testing functions available.

8. Auto Zero Tracking, Segmenting Span Correction, Speed Calibration and Belt Length Calibration functions available.

9. One optional ‘Flow Set Point’ analog signal input [AI: 4~20mA].

10. Max.3 definable ‘Flow/Control Current /…’ analog signal outputs [AO: 4~20mA].

11. Double-quick and steady feeding closed-loop control function available.

12. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

13. The feeder and belt scale can be started or stopped by DI&DO signals.

14. One ‘Totalized Weight High-speed Pulse’ output [

15. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

16. Support industry configuration software, e.g. iFix.

17. Weight Records per shift/day/month of a year can be queried and printed. | |||||

| > Add to cart | ||||||

| Hopper Weighing Controller BST100-B21 BST100-B21 1. Suitable for hopper weighing scale, platform scale, auto ration feeding&batching scale (single-material with two-speed ration feeding mode and three-material with single-speed ration feeding mode), axle weighing scale and peak weighing scale.

2. EMC design with high anti-jamming capability, suitable for industrial environments.

3. Model LED: 6 bit red LED display screen with English character display; 64-segment LED display with percent display.

4. Model VFD: 6 bit green VFD display screen with English character display.

5. Menu&Shortcut mode operation with key tone.

6. High-precision ∑-△A/D conversion module, 130,000 internal code [weighing signal AD value].

7. Special filtering algorithm for ensuring the weighing stability and occuracy when there is strong vibration on the load receptor, and the rapid response capability when the weight signal changes.

8. Max. Connection Quantity: 8 Loadcells (350Ω).

9. Data Calibration [when it’s not easy to do Load Calibration] and Load Calibration available.

10. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and Zero auto-tracking available.

11. One definable weight analog signal output [AO: 4~20mA].

12. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

13. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

14. Support industry configuration software, e.g. iFix.

15. Hopper weighing report, ration feeding report, auto-batching report, axle weighing report and peak value weighing report can be printed. | |||||

| > Add to cart | ||||||

.gif) | Hopper Weighing Controller BST106-B11 BST106-B11 1. Suitable for hopper weighing scale, platform scale, auto ration feeding&batching scale (single-material with two-speed ration feeding mode and three-material with single-speed ration feeding mode), axle weighing scale and peak weighing scale.

2. EMC design with high anti-jamming capability, suitable for industrial environments.

3. Model LED: 6 bit red LED display screen with English character display; 64-segment LED display with percent display.

4. Model VFD: 6 bit green VFD display screen with English character display.

5. Menu&Shortcut mode operation with key tone.

6. High-precision ∑-△A/D conversion module, 130,000 internal code [weighing signal AD value].

7. Special filtering algorithm for ensuring the weighing stability and occuracy when there is strong vibration on the load receptor, and the rapid response capability when the weight signal changes.

8. Max. Connection Quantity: 8 Loadcells (350Ω).

9. Data Calibration [when it’s not easy to do Load Calibration] and Load Calibration available.

10. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and Zero auto-tracking available.

11. One definable weight analog signal output [AO: 4~20mA].

12. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

13. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

14. Support industry configuration software, e.g. iFix.

15. Hopper weighing report, ration feeding report, auto-batching report, axle weighing report and peak value weighing report can be printed. | |||||

| > Add to cart | ||||||

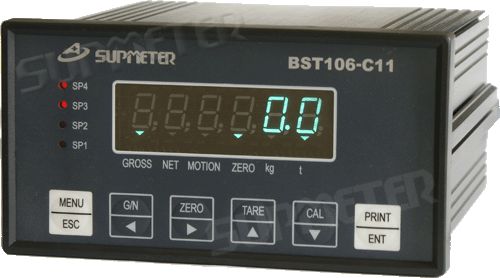

| Hopper Weighing Controller BST106-C11 BST106-C11 1.Suitable for hopper weighing scale, platform scale, auto ration feeding&batching scale (single-material with two-speed ration feeding mode and three-material with single-speed ration feeding mode), axle weighing scale and peak weighing scale.

2.EMC design with high anti-jamming capability, suitable for industrial environments.

3.Model LED: 6 bit red LED display screen with English character display; 64-segment LED display with percent display.

4. Model VFD: 6 bit green VFD display screen with English character display.

5.Menu&Shortcut mode operation with key tone.

6.High-precision ∑-△A/D conversion module, 130,000 internal code [weighing signal AD value].

7.Special filtering algorithm for ensuring the weighing stability and occuracy when there is strong vibration on the load receptor, and the rapid response capability when the weight signal changes.

8.Max. Connection Quantity: 8 Loadcells (350Ω).

9.Data Calibration [when it’s not easy to do Load Calibration] and Load Calibration available.

10.Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and Zero auto-tracking available.

11.One definable weight analog signal output [AO: 4~20mA].

12.Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

13. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

14.Support industry configuration software, e.g. iFix.

15.Hopper weighing report, ration feeding report, auto-batching report, axle weighing report and peak value weighing report can be printed. | |||||

| > Add to cart | ||||||

| Hopper Weighing Controller BST106-C11 BST106-C11 1. Suitable for hopper weighing scale, platform scale, auto ration feeding&batching scale (single-material with two-speed ration feeding mode and three-material with single-speed ration feeding mode), axle weighing scale and peak weighing scale.

2. EMC design with high anti-jamming capability, suitable for industrial environments.

3. Model LED: 6 bit red LED display screen with English character display; 64-segment LED display with percent display.

4. Model VFD: 6 bit green VFD display screen with English character display.

5. Menu&Shortcut mode operation with key tone.

6. High-precision ∑-△A/D conversion module, 130,000 internal code [weighing signal AD value].

7. Special filtering algorithm for ensuring the weighing stability and occuracy when there is strong vibration on the load receptor, and the rapid response capability when the weight signal changes.

8. Max. Connection Quantity: 8 Loadcells (350Ω).

9. Data Calibration [when it’s not easy to do Load Calibration] and Load Calibration available.

10. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and Zero auto-tracking available.

11. One definable weight analog signal output [AO: 4~20mA].

12. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

13. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

14. Support industry configuration software, e.g. iFix.

15. Hopper weighing report, ration feeding report, auto-batching report, axle weighing report and peak value weighing report can be printed. | |||||

| > Add to cart | ||||||

| Hopper Weighing Controller BST106-C21 BST106-C21 1. Suitable for hopper weighing scale, platform scale, auto ration feeding&batching scale (single-material with two-speed ration feeding mode and three-material with single-speed ration feeding mode), axle weighing scale and peak weighing scale.

2. EMC design with high anti-jamming capability, suitable for industrial environments.

3. Model LED: 6 bit red LED display screen with English character display; 64-segment LED display with percent display.

4. Model VFD: 6 bit green VFD display screen with English character display.

5. Menu&Shortcut mode operation with key tone.

6. High-precision ∑-△A/D conversion module, 130,000 internal code [weighing signal AD value].

7. Special filtering algorithm for ensuring the weighing stability and occuracy when there is strong vibration on the load receptor, and the rapid response capability when the weight signal changes.

8. Max. Connection Quantity: 8 Loadcells (350Ω).

9. Data Calibration [when it’s not easy to do Load Calibration] and Load Calibration available.

10. Auto-locking, Key-locking, Key-unlocking, digital setting&calibration and Zero auto-tracking available.

11. One definable weight analog signal output [AO: 4~20mA].

12. Three definable normally open switch inputs [DI] and four definable normally open relay or transistor switch outputs [DO].

13. Two optional communication ports for linking to IPC/PLC, remote display&operation terminal, serial printer, wireless module, etc.

14. Support industry configuration software, e.g. iFix.

15. Hopper weighing report, ration feeding report, auto-batching report, axle weighing report and peak value weighing report can be printed. | |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2026 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||