|

| < Back | ||||||

| Zhengzhou Deyi Heavy Industrial Machinery Manufacturing Co., Ltd | ||||||

| About this company : Zhengzhou Dearye Heavy Industrial Machinery Manufacturing Co., Ltd. is a modern high-tech enterprise established jointly with a state-level research institute. Located at the Economic and Technical Development Zone of Zhengzhou, capital of Henan province, the company has an area of 35 thousand sqm, fixed assets over 36 million RMB, with engineering and technical personnel covering 20% of the total employees. It is member of China Brick and Tile Association and member of China Sand Association. The company integrates scientific research, production and marketing with national standard management, and it has passed the ISO9001:2000 quality system authentication. In 2006, the company has been recognized by Ministry of Commerce and gained the independent Import and Export Right of machinery products. Our main products are DY block making machine series,crusher series, grinding mill series,stone production line,AAC equipments. Especially,the DY multi-functional hydraulic brick making machine always take the lead in this field. Product quality is the lifehood of Dearye Brand. Reliable and stable quality is the promise of Dearye people. Dearye is making every effort to create high quality products and service for all the customers. | ||||||

| Contact : S Y | ||||||

| Headquarters : Jingnansan Rd., Zhengzhou, Henan, 450016, China | ||||||

| Phone : 86-371-66162000-806, Fax : 86-371-86020709 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

| ball mill DEYI Ball Mill Introduction: Ball Mill Application

The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process. We have various of ball mill such as 900*1800, 900*2100, 900*3000, 1200*2400, 1200*2800, 1200*4500, 1500*3500, 1500*4500, 1500*5700, 1830*7000 etc. In order to give you a responsible quotation, you can inform us the following information: 1. What's the material you are going to deal with? 2. What's the granularity of the material? 3. What's the granularity of the final products are you going to achieve? 4. What's the producing capacity you are going to achieve? Our engineers will suggest you the most suitable one for you according to your information | |||||

| > Add to cart | ||||||

| aac block machine DEYI We are a leading manufacturer of block making machinery in China with a history of 15 years. We have several kinds of AAC block production line to make different kinds of bricks/blocks with different capacities. Our AAC production line is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea .Our equipment is advanced, , we use Aerial tumbling cutting units .PLC automatic ingredient, complete electric control system will help you improve efficiency and save cost .

1. aerated concrete/aerated brick blocks raw material storage and the materials

2. Aerated concrete/aerated brick blocks raw material processing 3. aerated block ingredients, mixing, pouring 4. aerated block early sanatorium and cutting 5. aerated block autoclaved and finished product Our company designed aerated brick production line project, has reached the leading level in the same domestic equipment, the production aerated concrete block compressive strength can achieve 5.0 - a magnitude 7.5, shrinkage less than 0.8 mm/m, its high quality, light weight, penetration-proof quality good, sound insulation, heat insulation, heat preservation, seismic fine performance, the shape dimension precision, the damage rate is close to zero level. And the technological superior manufacture troop, complete quality guarantee system, ensure the product processing and assembling accuracy, so as to ensure the stability and reliability of our products. | |||||

| > Add to cart | ||||||

| aac casting machine DEYI Purpose of the Casting Machine:

| |||||

| > Add to cart | ||||||

| aac cutting machine DYKF AAC Blocks Cutting :Turns over the hoisting mechanisms airborne to turn over together the mold belt body on 90 degree laying aside cutting car, the drawing of patterns keeps the body together with the side bar cuts on the car, cutting car to make the power by the electrical machinery to walk, completes longitudinal cutting, the milling, level cutting through the slitting installment; Cutting car continues to walk after the infeed set-up central location stop, the infeed set-up starts, transverse cutting vertical undercuts from the top downward completes the across cutting; Cutting car to walk again to the grouping hoisting mechanisms place (side bar hangs continually) by the grouping hoisting mechanisms the body to steams raises on the car, cutting car to return to the initial position to carry on the next cutting circulation. Aerial tumbling cutting units

1. The machine structure is simple and practical, the maintenance is easy; 2. The green cake is sideward, so the width of the whole green cake is 600mm, and the height is 1200mm. Steel wires for cutting is short, which is also difficult to rupture and float. It is high in cutting precision; 3. The vertical cutting device is fixed. Crosscut device cuts the green cake vertically by steel wires. It shortens the cutting steel wires length, guarantee precision of cutting; 4. This machine cuts the green cake in Hexahedron-type, so the products quality wont be influenced by the distortion of the mould; 5. Cylinder Tension, which supply gas to each wire respectively; 6. Avoiding the wires being stretched off by using a special device; 7. Life of the wire can extend (Usually 10 days, Now 20 days); 8. Operating it in use of the computer touch panel, realize separation of Man-Machine. | |||||

| > Add to cart | ||||||

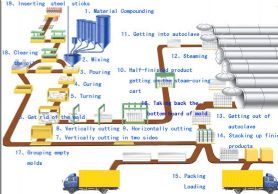

| aac machine DEYI aac machine We are a leading manufacturer of block making machinery in China with a history of 15 years. We have several kinds of AAC block production line to make different kinds of bricks/blocks with different capacities. Our AAC production line is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea .Our equipment is advanced, , we use Aerial tumbling cutting units .PLC automatic ingredient, complete electric control system will help you improve efficiency and save cost . The aac block machine production line process: | |||||

| > Add to cart | ||||||

| aac machine DEYI aac machine We are a leading manufacturer of block making machinery in China with a history of 15 years. We have several kinds of AAC block production line to make different kinds of bricks/blocks with different capacities. Our AAC production line is importing German advanced equipment, through digesting, design and more perfect, our production line is popular in home and oversea .Our equipment is advanced, , we use Aerial tumbling cutting units .PLC automatic ingredient, complete electric control system will help you improve efficiency and save cost . The aac block machine production line process: | |||||

| > Add to cart | ||||||

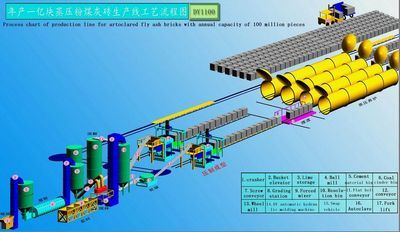

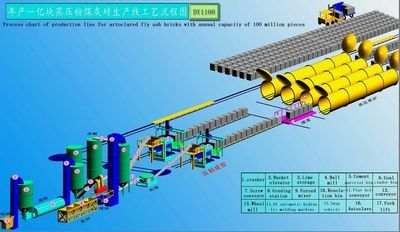

| autoclaved fly ash brick machine DYS850 Our company provide fly ash autoclaved brick quipment,lime-sand brick machine,with good quality and competitive price .suggested the brick machine and supporting equipments etc series autoclaved brick of complete sets of equipment of professional manufacturers. Production of fly ash autoclaved brick equipment bring the users considerable economic benefit. The process of fly ash autoclaved brick production line:

The massive lime crushing,grinding with stone breadcrumbs,fly ash after respectively storage,after respectively metering,mixing with water,digestion,wheel grinding machine crushes the mixture,and then sent to DEYI automatic hydraulic brick machine,forcing molding.Automatic setting machine put the finished-blocks into autoclave car,within the autoclaves for maintenance by ferry vehicle,After out from autoclave kettle,the finished brick will be sent to finished product yard,store 10 days can be selled.Empty autoclaved car after cleaning to return automatic brick machine for next turn. | |||||

| > Add to cart | ||||||

| block machine DY850 Machine/Block Machine 4. save power and Popular In Overseas Market 3. This series products is full-fledged , technique is advanced ,to produce all kinds of blocks , and their qultity is good , is high (load bearing block can arrive 20Mpa), geometry dimension is exact so on virtues(dimension error make sure within 1.5mm) 4. Using advanced screw net to lay material , which can make the material kinds extensive(liking sand, stone chips , slag, coal gangue, coal cinder ,coal ash and some construction waster etc.)they are enviromental machine conpare with other block s machine. 5. This machine realized mechanical , electronic and liquid integration ,PLC computer control automatically , hydraulic drive, machine vibration and hydraulic press to make block moulding, computer monitoring and control every link , which can realize error lock automatically, error detection and capcaity statistics. make the block density better , cement qulinty is more littler. 6. It can produce block all day whatever the south ,north, which is one block making plant that is cheap for invest , faster reasult , operate easily, maintenance handly. 7. Don't need change any accessory ,only need call the program so that can produce load and unload block;it can produce you need only change different mould. 8. Our block machines are based on the advanced aborad machine characteristic ,This machine virtues such as , structre is good , look beautiful , highly durable , maintain rate is low, degree fo atuomationcis advanced, which utlize two oil cylinders. | |||||

| > Add to cart | ||||||

| block machine DYS850 Brick Making Machine/Block Machine 1. good quality and Competitive Price 2. durable and Long Service Life 3. nice shape and Excellent Performance 4. save power and Popular In Overseas Market 1. Utilze machinery and mould vibration , make the block density and strongbest, it is better than only single vabiration, because of the work desk is v wide , to make the vibration spread equably, down vibration utlize double hands vibration, two oil motor make two vibration case correlate. 2. Material vehicle mechanism utlize screw net, which make laying material equably , shorten the time of round trip for material vehicle ,Accordingly shorten the moulding cycle. 3. This series products is full-fledged , technique is advanced ,to produce all kinds of blocks , and their qultity is good , is high (load bearing block can arrive 20Mpa), geometry dimension is exact so on virtues(dimension error make sure within 1.5mm) 4. Using advanced screw net to lay material , which can make the material kinds extensive(liking sand, stone chips , slag, coal gangue, coal cinder ,coal ash and some construction waster etc.)they are enviromental machine conpare with other block s machine. 5. This machine realized mechanical , electronic and liquid integration ,PLC computer control automatically , hydraulic drive, machine vibration and hydraulic press to make block moulding, computer monitoring and control every link , which can realize error lock automatically, error detection and capcaity statistics. make the block density better , cement qulinty is more littler. 6. can produce block all day whatever the south ,north, which is one block making plant that is cheap for invest , faster reasult , operate easily, maintenance handly. 7. Don't need change any accessory ,only need call the program so that can produce load and unload block;it can produce you need only change different mould. 8. Our block machines are based on the advanced aborad machine characteristic ,This machine virtues such as , structre is good , look beautiful , highly durable , maintain rate is low, degree fo atuomationcis advanced, which utlize two oil cylinders. | |||||

| > Add to cart | ||||||

| fly ash brick machine DYS850 The process of fly ash autoclaved brick production line:

| |||||

| > Add to cart | ||||||

| impact crusher DEYI Features of impact crusher: 4. crusher with Less machine stop time 8. High crushing ratio; 9. Easy maintenance; Brief introduction of impact crusher: The impact crusher is mainly used to crush many kinds of large, medium, small materials such as rock or stone whose side length is less than 500mm, and compression resistance should not be more than 350Mpa. The crusher is widely used in hydroelectricity, highway, artificial rock, stone and sand, building material, etc. Working Principle of Impact Crusher: | |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2025 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||