|

| < Back | ||||||

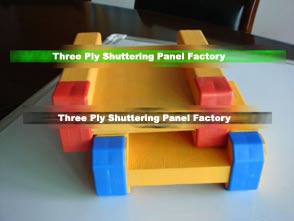

| Three Ply Shuttering Panel Factory | ||||||

| About this company : Dear Sir/Madam, Welcome to ubest!!! We are one of the leading group of manufacturers of engineering wood products in South China. We mainly export plywood, Laminated Veneer Lumber, Three Ply Shuttering Panels(triply), formwork H20 Timber Beam (Wood Girder), film faced plywood, HDF, MDF (medium density fibreboard), particle board, Softwood Scaffold Panel(Pine LVL scaffolding Plank), 3 ply panel, Shuttering Plywood, melamine board, Pine Plywood, HMR MDF, blockboard, OSB board, etc. Our products meet E1/E2 Standard. For more, please contact us freely. We offer free samples. Note that we only reply fax or electronic mail inquiry. We have quotation lists in hand and looking forward to your enquiry. Best Regards, Belinda Shi Login to contact us right away | ||||||

| Contact : Belinda Shi, sales | ||||||

| Headquarters : No. 22, Lvling Road, xiamen, Fujian, 361004, China | ||||||

| Phone : 0086-15959253593, Fax : 0086-592-5594747 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

| 3 ply shuttering panel For construction use, the function of the 3 layer shuttering panel is the same as film faced plywood. Three Ply Shuttering Panels are made of 3-plywood with a thickness of 9 mm each ply. The 1st and the 3rd ply grain are arranged at right angles to the second ply. Both sides of the panels have a melanimic protection in light yellow colour and alkaline proof and to avoid humidity. Glueing is made with high temperatures and pressure. The moisture content is less than 13%. Size: 970 x 500 mm 1000 x 500 mm 1500 x 500 mm 1970 x 500 mm 2000 x 500 mm 2500 x 500 mm 3000 x 500 mm Thickness: 21mm (3 x 7mm),27mm (3 x 9mm). Glue: WBP (MUF) / E1. Density: 425Kgs/M3. Material: Fir/Abisia. Sanding: Double faced sanded and Coated. | |||||

| > Add to cart | ||||||

| film faced plywood Base plywood Pine, Popar, Birch or Combi Plywood Bonding WBP exterior, Coating Brown phenolic film 120 g/m2 on both sides, alternatively Black 220-240 g/m2 on both sides Edge treatment Brown acrylic paint or Silver, Purple silicon paint against moisture pick up Thicknesses 12, 15, 18, and 21 mm Sizes 1220/1250 x 2440/2500 mm | |||||

| > Add to cart | ||||||

| formwork plywood Base plywood Pine, Popar, Birch or Combi Plywood Bonding WBP exterior, Coating Brown phenolic film 120 g/m2 on both sides, alternatively Black 220-240 g/m2 on both sides Edge treatment Brown acrylic paint or Silver, Purple silicon paint against moisture pick up Thicknesses 12, 15, 18, and 21 mm Sizes 1220/1250 x 2440/2500 mm | |||||

| > Add to cart | ||||||

| h2 beam For construction use. Carry film faced plywood. Made of high-grade solid sawn Pine lumber and Pine plywood. Prefabricated wood H 20 Beams are manufactured in a range of sizes. Long lengths use fingerjoining to splice flanges and butt jointing or toothed, tongue and groove or scarf configurations to splice the webs. The actual length is limited only by transportation restrictions Weight per running meter: 5.2-5.8 kg Mechanical specification: Bending moment – max.5 kN.m Cutting action – max 11.0KN Bending – max1/500 Live load (Bending Stiffness) – max 500 kN/m2 Length in cm 180 - 245 - 290 - 330 - 360 - 390 - 420 - 450 - 460 - 490 - 590 | |||||

| > Add to cart | ||||||

| h2 wood beam For construction use. Carry film faced plywood. Made of high-grade solid sawn Pine lumber and Pine plywood. Prefabricated wood H 20 Beams are manufactured in a range of sizes. Long lengths use fingerjoining to splice flanges and butt jointing or toothed, tongue and groove or scarf configurations to splice the webs. The actual length is limited only by transportation restrictions Weight per running meter: 5.2-5.8 kg Mechanical specification: Bending moment – max.5 kN.m Cutting action – max 11.0KN Bending – max1/500 Live load (Bending Stiffness) – max 500 kN/m2 Length in cm 180 - 245 - 290 - 330 - 360 - 390 - 420 - 450 - 460 - 490 - 590 | |||||

| > Add to cart | ||||||

| three ply shuttering panels For construction use, the function of the 3 ply shuttering panel is the same as film faced plywood, in various countries, constructions adopt alternative film faced plywood, shuttering plywood, or 3 ply shuttering panels. The advantages of 3 ply shuttering panels against film faced plywood: Light weight Longer service life than poplar film faced plywood. Save shipping cost. Because of the light weight, more quantity can be loaded in the container. Three ply shuttering panel is made of 3-plywood with a thickness of 9mm each ply. The 1st and the 3rd ply grain are arranged lengthwise, and the 2nd ply is arranged crosswise. Glueing is made with high temperatures and pressure. The moisture content is less than 13%. Both sides of the panels have a melanimic protection in orange color and alkaline proof to avoid humidity. Shuttering Panel is made of Fir Lumber, with wearable yellow WBP glue hot temperature treated coating surface. All edges are sealed by water-proof painting. Product range: Thickness: 27mm (9+9+9); 21mm (7+7+7) Width: 500mm (We also can produce the special width according to your request.) Length: 970mm, 1000mm, 1500mm, 2000mm, 2500mm, 3000mm. | |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2025 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||