|

| < Back | ||||||

| Baytree Packaging Material Corporation | ||||||

| About this company : Our company production technical craft of coated film and the products quality occupies the internal leading status at present. The sales market mainly faces to foreign market. Our company locate in the Changjiang delta economy circle, occupies 66,000 square meters with extremely ascendant geography condition. We take the technology as forerunner, capital as supporter to try all effects to make the country prosperous and insist on producing generation and stockpile generation development idea, unceasingly promote the products adapt to the requirements of foreign market. We owned the all sealed 100,000 Cleanliness high standard workshop comply with GMP, ultra power air-conditioning setting guarantee the constant temperature and humidity all over of the producing process. With the hygienic resin raw material and imported assistant material (Germany, America, Japan, Korea), made the produced products has a clear and bright appearance, toughness and intensity achieved the best balance. The capability that suit for two times machining is very excellence, shape-full, tenacity and highly heat sealing intensity and non-leakage phenomenon. Complete establishment testing department with rigorous and careful quality testing personnel, have used the strict supplier examination system in addition. Supplying channel for original and assistant material decades sees like a day, stable production quality, obtained clients deep dependence. Presently, our products are normally exported to America, Russia, France, Holland, Spain, Ukraine, Bulgaria, Lebanon, Bangladesh, Saudi Arabia and Iran. Company name: Baytree Packaging Material Corporation Address: No.8 NanerHuan Road Taixing Jiangsu Zipcode: 225400 Tel: +86 523 87713900 / 82826000 Fax: +86 523 87713700 Login MarginUp for more information. | ||||||

| Contact : Vicky Zhang , sales | ||||||

| Headquarters : No.8 Nanerhuan Road, Taixing, Jiangsu, 225400, China | ||||||

| Phone : +86-523-87713900, Fax : +86-523-87713700 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

.jpg) | PET/ PE/ EVOH/ PE coated film EVOH can be regarded as EVA modified material. It has both ethylene polymer good process capability and vinyl alcohol polymer high gas obstruct capability. It is a new colorless, transparent obstruct material, with PVDC and PA, these three materials are the best barrier resin in the world. Its gas obstruct capability is 100 times higher than PA, 10000 times higher than PE,PP and ten times higher than PVDC which high obstruct material we used very often. In dry or relative humidity condition, its permeability is extremely low, but its gas barrier capability is 10 to 50 times or even more times higher than Nylon. EVOH has excellent transparency, glossiness, mechanical strength, retractility, abrasive resistance, freeze resistance and surface strength. It has the highest heat stability in all the barrier resins. It also has excellent oil resistance, organic solvent resistance and antistatic capability. It can regenerate and does not contain Chlorine and Dioxin,it is to be called green environmental production. According to the use of soft packaging, you must considered the material process capability and physics capability, to choose 10 to 20 times EVOH as the barrier layer, not only prevent oxygen and water vapor infiltrating into the content, but also chain up the aroma, fluid juice and the solvent of the content. Thus it solved the problem that the contents (liquid, gas) dissolved the compound water glue. In some areas, the EVOH has gradually replace the metallized film, aluminum foil and rigid container. It is being received various countries attention and shows the best potential growth trend in the market. Due to the oxhydryl in the molecular structure of EVOH resin, EVOH resin has the hydrophilia and hygroscopicity. When it adsorb the damp, its gas obstruct capability will be affected. So EVOH is used as the middle layer, usually coated with polyolefin. The damp quantity can be control aboratively, to use multilayers coated technic to packing EVOH resin (such as polyolefin). After many years research, we discovered that if we select the international import raw materials, use the latest co-extruded process flow, the production which contains the EVOH high obstruct ability. Then compound many kinds of base materials like PE, PP, PVC, polystyrene, PET, PA and so on. The Oxygen transmission rate can be reduced to a small percentage even one thousandth. According the requirement of the obstruct effect, it can be coated on single side or double sides or even multilayer coated. The production of multilayer coated film for the automatic liquid filling machine, not only solved the moisture absorption problem, but also had a good economical efficiency. To each kind of active ingredient, the low adsorbability, high obstruct capability, it can prevent the loss of effective component; the excellent oxygen resistance, can prevent the oxidation and metamorphism of the effective component; the excellent transparency, can be applied to the oxygen sensitive goods. The packaging content can be solid granules, powdery products, fluid products. | |||||

| > Add to cart | ||||||

.jpg) | Officinal PVC film Our company main produce solid Pharma-grade PVC rigid film, it takes high marking health level PVC resin as the main raw material, complements with import top-grade accessorial material. Not only the product thickness is even, transparent and clean, but also has good anti-impact, anti-corrosion, anti-aging, anti-ultraviolet radiation, easy to take shape, heat sealing quickly and so on characteristics. It is the ideal packing material for all kinds of medicine(tablet, capsule, injection, take orally fluid). Colored Pharma-grade PVC film produced mainly by high standard Pharma-grade PVC resin together with suitable amount of coloring agent and processing aid, come into product after clashing. The product not only maintained the fine performance which PVC film has, but also had certain evaded the light function and the artistic function is the ideal packing material for all kinds of medicine(tablet, capsule, injection, take orally fluid). | |||||

| > Add to cart | ||||||

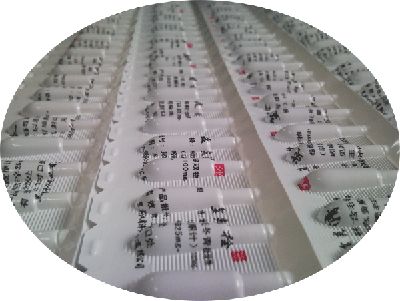

| Officinal PVC/PE for Suppository Packaging Officinal PVC/PE for Suppository Packaging After 30 years' study and improvement, our factory takes officinal PVC rigid film as the base maretial,then heat sealing of PE film,the material is situable for all kinds of domestic or import equipment.Due to its excellent physical and chemical characteristics,at present,this material suits for mass-produce to bring the low cost.Now,it is the most popular new material for suppository packaging. Product characteristics PE has good heat sealing ability.During the practical processing,the material for packing suppository must have fine sealing effect for inside substance the meanwhile,it must be easy to be slited from the heating aspect.Therefore,the material structure needs high technology.After a large number of theoretical calculations and practice,our technical staff developped new material that molecular structure is reorganized.PVC/PE coated film not only has intensity,toughness and excellent gas obstruct ability with PVC,but also has high liquid barrier property and good heat sealing ability with PE can meet different customers' requirements after modest and targeted adjustment. PS:All of our products are produced in the 100,000 level depirative and sealed workshop.During production processing,the temperature,coated quantum,coated time and other improt considerrations are checked strictly to make the final products exceeding foreign similar products.If there is any volatile,please consult to use PVC/PVDC/PE coated film.This product has high obstruct ability can complete avoid the volatilization of the shortage quantity or other effect that affected the capability of the medicine. Baytree Packaging Material Corporation Address: No.8 NanerHuan Road Taixing Jiangsu Zipcode: 225400 Tel: +86 523 8771 3900 / 8282 6000 Fax: +86 523 8771 3700 Mobilephone: +86 135 1255 2047 Login MarginUp for more details. | |||||

| > Add to cart | ||||||

| PET/PE coated film Due to PE has good heat sealing ability, it can not obstruct the gas but it can obstruct the fluid very well. It is good for fluid medicine packing. Some factories used old glass bottles before, it has two fatal defects: 1 is easy broken when you are opening. 2.The fluid in it is easy to expanded and crash the bottle when it has fermented. So it will damage the product packaging. Officinal PET/PE coated film has kept away from the two defects above. It is mainly produced by officinal PET film, then heat seal PE film. During the producing, the temperature, coated quantum and solid time are measured strictly to make sure that the product can meet the standard of the same product in the international. The heat sealing ability is 4 times higher than common PVC film. It also has good rigidty, flexility, cash resistance and dilatability. It is suitable for packing all kinds of fluid medicine. PS: If there is any volatile, please consult to use PVC/PVDC/PE coated film. This product has high obstruct ability. It can complete avoid the volatilization of the shortage quantity or the capability of the medicine will be affected. | |||||

| > Add to cart | ||||||

| PET/PVDC coated film In practical application process, added non-toxic PVC monomer which has the environmental protection ability on the clear PET surface , combined with PVDC good obstruct ability , it plays a good moisture-proof effect to the product in packing. PVDC material itself is the latex character, has quite big brittleness after the solidification. In the coating process and post-processing, the pivotal technical is to reduce its brittleness, make it normally used in the room temperature environment. Before, the technical ability is too poor to do so. That is one of the technical difficulties of PVDC compound material. On the basis of oversea craft brother experience, our technician first produces successfully in . It mainly takes PET film as the basal material, then coated PVDC(import from BASF in Germany). During the production processing, the temperature, coated quantity and times and other important considerations are checked strictly to make the final product meet the foreign products quality standards. The obstruct ability is 5 times higher than the common PVC. Meantime it has a certain rigidity, flexible and can be widely used in packaging various solid medicine, especially for easy humidity absorb medicine. Remarks: According to the investigation, presently 80% medicine using such packaging materials, but the PVC film that widespread used in could infiltrate the gas and liquor 6 months later in the room temperature condition. The product will cause toxic effects. At present, developed countries all forbid using PVC to contact medicine directly. | |||||

| > Add to cart | ||||||

| PVC/ PE/ EVOH/ PE coated film EVOH can be regarded as EVA modified material. It has both ethylene polymer good process capability and vinyl alcohol polymer high gas obstruct capability. It is a new colorless, transparent obstruct material, with PVDC and PA, these three materials are the best barrier resin in the world. Its gas obstruct capability is 100 times higher than PA, 10000 times higher than PE,PP and ten times higher than PVDC which high obstruct material we used very often. In dry or relative humidity condition, its permeability is extremely low, but its gas barrier capability is 10 to 50 times or even more times higher than Nylon. EVOH has excellent transparency, glossiness, mechanical strength, retractility, abrasive resistance, freeze resistance and surface strength. It has the highest heat stability in all the barrier resins. It also has excellent oil resistance, organic solvent resistance and antistatic capability. It can regenerate and does not contain Chlorine and Dioxin,it is to be called green environmental production. According to the use of soft packaging, you must considered the material process capability and physics capability, to choose 10 to 20 times EVOH as the barrier layer, not only prevent oxygen and water vapor infiltrating into the content, but also chain up the aroma, fluid juice and the solvent of the content. Thus it solved the problem that the contents (liquid, gas) dissolved the compound water glue. In some areas, the EVOH has gradually replace the metallized film, aluminum foil and rigid container. It is being received various countries attention and shows the best potential growth trend in the market. Due to the oxhydryl in the molecular structure of EVOH resin, EVOH resin has the hydrophilia and hygroscopicity. When it adsorb the damp, its gas obstruct capability will be affected. So EVOH is used as the middle layer, usually coated with polyolefin. The damp quantity can be control aboratively, to use multilayers coated technic to packing EVOH resin (such as polyolefin). After many years research, we discovered that if we select the international import raw materials, use the latest co-extruded process flow, the production which contains the EVOH high obstruct ability. Then compound many kinds of base materials like PE, PP, PVC, polystyrene, PET, PA and so on. The Oxygen transmission rate can be reduced to a small percentage even one thousandth. According the requirement of the obstruct effect, it can be coated on single side or double sides or even multilayer coated. The production of multilayer coated film for the automatic liquid filling machine, not only solved the moisture absorption problem, but also had a good economical efficiency. To each kind of active ingredient, the low adsorbability, high obstruct capability, it can prevent the loss of effective component; the excellent oxygen resistance, can prevent the oxidation and metamorphism of the effective component; the excellent transparency, can be applied to the oxygen sensitive goods. The packaging content can be solid granules, powdery products, fluid products. | |||||

| > Add to cart | ||||||

| PVC/PE/PVDC coated film PVC/PE/PVDC coated film, in practical application process, PVDC has a good obstruct ability, but also has a large brittleness. Some foreign companies add PE between PVC and PVDC, the brittleness of PVDC have solved and the intermediate PE will have a great benefit in total toughness in packaging. PVDC material itself is the latex character, has quite big brittleness after the solidification. In the coating process and post-processing, the pivotal technical is to reduce its brittleness, make it normally used in the room temperature environment. Before, the technical ability is too poor to do so. That is one of the technical difficulties of PVDC compound material. On the basis of oversea craft brother experience, our technician first produces successfully in . It mainly takes PVC film as the basal material, then coated PVDC(import from BASF in Germany). During the production processing, the temperature, coated quantity and times and other important considerations are checked strictly to make the final product meet the foreign products quality standards. The obstruct ability is 5 times higher than the common PVC. Meantime it has a certain rigidity, flexible and can be widely used in packaging various solid medicine, especially for easy humidity absorb medicine. Remarks: According to the investigation, presently 80% medicine using such packaging materiahs, but the PVC film that widesppead used in could infiltrate the gas and liquor 6 months later in the room temperature condition. It has a great impact on the product. But if using PVDC, the period for protection to medicine can really reach at least 2 years. | |||||

| > Add to cart | ||||||

| PVC/PVDC/PE coated film PVC/PVDC/PE coated film is add high obstract material PVDC between PVC and PE. In practical application process, put liquid in PVC/PE compound film, if there is any liquid which has strong volatility, after a period of time stored, the liquid will volatilize, the quantity will reduce and the face of the product will inward depression. It will reduce the effective protection capablity of the medicine. Seriously, it will cause the disput with consumers. Then the economy and the image of the company will be damaged. Due to the good obstruct ability of PVDC, it plays a good anti-infiltrate effect to the product in packing, it is the ideal packaging material for easy humidity absorb medicine. PVDC material itself is the latex character, has quite big brittleness after the solidification. In the coating process and post-processing, the pivotal technical is to reduce its brittleness, make it normally used in the room temperature environment. Before, the technical ability is too poor to do so. That is one of the technical difficulties of PVDC compound material. However, the three compound processing technology is more difficult. At present, only few companies which has independent research and development ability can do it in . My company starts from 1980s, after a few years research and testing, finally succeeded in produce the PVC/PVDC/PE costed film which is truly apply to the liquid packaging. It mainly takes PVC film as the basal material, then coated PVDC(import from BASF in Germany) and PE . During the production processing, the temperature, coated quantity and times and other important considerations are checked strictly to make the final product meet the foreign products quality standards. The obstruct ability is 5 times higher than the common PVC. Meantime it has a certain rigidity, flexible and can be widely used in packaging various easy volatile medicine. The period for protection can really reach the required standard. According to the investigation, presently 80% medicine using such packaging materials, but the PVC film that widespread used in could infiltrate the gas and liquor 6 months later in the room temperature condition. It has a great impact on the product. But if using PVDC, the period for protection can really reach at least 2 years. PE has good heat seal ability, PVC/PVDC/PE coated film has combined their respective merit to form a new special ideal packaging material. | |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2025 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||