|

| < Back | ||||||

| Dengfeng Jinyu Thermo-Electric Material Co., Ltd | ||||||

| About this company : Dengfeng jinyu Thermo-electric Material Co., Ltd is a high-tech enterprise through ISO 9001: 2000 quality management system certification, and our factory got the honor of environmental protection. Our leading products include molybdenum disilicide heating elements, MoSi2 heating elements, Silicon Carbide heating elements, SiC Heating Elements, silicon carbide, silicon carbide rods, silicon carbide heater, SiC heater, MoSi2 heater, molybdenum disilicide heater, silicon carbide roller, heating elements, tube furnace, muffle furnace, chamber furnace, box furnace, high temperature furnace, glass furnace, molybdenum, moly, molybdenum heater, molybdenum heating elements, molybdenum electrode, molybdenum rods, molybdenum bars, molybdenum boats, molybdenum plate, molybdenum wire, molybdenum foils, molybdenum crucible, alumina crucible, alumina tube. molybdenum targets, Molybdenum parts, Molybdenum ring, Molybdenum fabricated plate, Molybdenum hoop, Molybdenum electrodes inserts, Molybdenum discs, Molybdenum bolts, molybdenum nozzle, contact, Mr. Amos Guo Login to contact me. Thanks for your choosing products from Jinyu. | ||||||

| Contact : Amos Guo, manager | ||||||

| Headquarters : songyang road, dengfeng, zhengzhou, henan, 452470, China | ||||||

| Phone : 86+371-62768555, Fax : 86+371-62768366 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

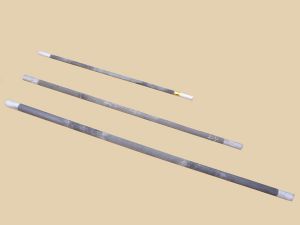

| silicon carbide heating elements Jinyu Silca SiC heating element is a type of non-metal high temperature heating device. These SiC productsare made from fine quality green silicon carbide as its main raw material. The raw material is made first in to a blank, followed by high temperature silication and recrystallization, and becomes high quality stick shaped SiC electric heating devicespared with metal electric heating material, this type of non-metal elements is featured of high operation temperature, anti-oxidization, long service life, little deformation, easy installation and maintenance. Because of these advantages, SiC electric heating elements is widely used in various industries that require high temperature electric furnaces and heating devices. These typical applications include electronics, magnetic materials, powder metallurgy, ceramics, glass, metallurgy and machinery. We adopt new production process of cold end, so Jinyu Silca heating elements have excellent specific rate of heat zone resistance and cold end resistance, saving energy, long life, avoiding over-temperature of cold ends damaging furnace body. Products specification: Rod type, U type, W type (Three Phase type), Solid Rod type, Spiral type, 5 piece type (dual hot zone). Sizes are available from Dia 12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm, 31.7mm (1.25inch), 35mm, 38.1mm (1.5 inch), 40mm, 44.4mm (1.75 inch) to 54mm (2.125 inch) for all types. Login for more details. Contacto, Mr, Amos Guo | |||||

| > Add to cart | ||||||

| molybdenum crucibles Molybdenum Crucible 1. Specification of Tungsten and Molybdenum Crucible: Diameter of 10-400mm Length of 10-6000mm 2. The Tungsten Crucible and Molybdenum Crucible are pure tungsten or pure molybdenum materials. 3. Usage: The Tungsten Crucible and Molybdenum Crucible can all be the container for rare earth smelting. We supply a wide range of molybdenum products including electrode, wire, foil, sheet, plate, rod, strip, boats, crucibles, tube, alloys and etc. Contact: Mr. Amos Guo Login MarginUp for more details. | |||||

| > Add to cart | ||||||

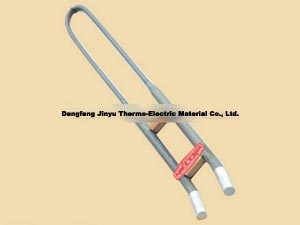

| molybdenum disilicide heating elements MoSi2 heating element is a kind of restance heating element based on molybdenum disilicide. In oxidizing atmosphere, the molybdenum disilicide heating elements prevents the inner core from oxidation by forming a compact quartz glass coating at the surface under high temperature, its Max temperature can reach 1800. MoSi2 heating element can usually make use of furnace temperature from 1300 to 1800. It is extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacture, etc. It is an essential ideal element when the products are sintering in the high temperature. The product includes series 1700 grade, 1800 grade. Packaging is available in U shape, W shape, Straight shape (X shape) and bend shape (L shape). The dimension ranges from 3/6, 4/9, 5/10, 6/10, 6/12, 6/14, 7/14, 8/16, 9/18 to 12/24mm. Contact: Mr. Amos Guo. Login to contact me right away. | |||||

| > Add to cart | ||||||

| molybdenum electrodes Molybdenum electrodes and molybdenum rod, It is find and close product with gray metallic lusternsity>10.2g/cm. Used for glass industry. It can serve a long life in glass solution at 1300 C. Also used in the fields of rare earth industry. We supply a wide range of molybdenum products including electrode, wire, foil, sheet, plate, rod, strip, boats, crucibles, tube, alloys and etc. Ordered manufactured to your specifications. Contact, Mr. Amos Guo. Login to trade with me right away. | |||||

| > Add to cart | ||||||

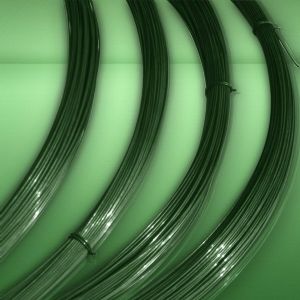

| molybdenum wires Molybdenum wire, Tungsten lamp filaments, which operate at temperatures in the range of 2400 C, are successfully mounted on molybdenum wires; the wire acting both as a heat sink and a support while lowering the temperature at the support junction. Likewise, molybdenum sees wide use in the construction of power tube grids and support structures which also require high temperature strength, low vapor pressure and low thermal expansion. High temperature vacuum and hydrogen atmosphere furnaces also rely on the use of molybdenum rod and molybdenum wire to form resistance heating elements. We supply a wide range of molybdenum products including electrode, wire, foil, sheet, plate, rod, strip, boats, crucibles, tube, alloys and etc. Contact: Mr. Amos Guo. Login to contact me. | |||||

| > Add to cart | ||||||

| MoSi2 heating elements MoSi2 heating element is a kind of restance heating element based on molybdenum disilicide. In oxidizing atmosphere, the molybdenum disilicide heating elements prevents the inner core from oxidation by forming a compact quartz glass coating at the surface under high temperature, its Max temperature can reach 1800. MoSi2 heating element can usually make use of furnace temperature from 1300 to 1800. It is extensively used in the industries of metallurgy, glass, ceramic refractory, crystal electronic device, industrial furnace manufacture, etc. It is an essential ideal element when the products are sintering in the high temperature. The product includes series 1700 grade, 1800 grade. Packaging is available in U shape, W shape, Straight shape (X shape) and bend shape (L shape). The dimension ranges from 3/6, 4/9, 5/10, 6/10, 6/12, 6/14, 7/14, 8/16, 9/18 to 12/24mm. Contact: Mr. Amos Guo. Login to trade with me. | |||||

| > Add to cart | ||||||

| muffle furnace The high temperature muffle / tube furnace used MoSi2 rods as heating element. Max. temperature inside furnace can be reached at 1650 degree. The furnace temperature profile can be set up by 30 segments and run automatically by the 708 type temperature controller. It is excellent for material research, industry, ceramic research labs. contact person: Mr Amos Guo. Login to contact me. The furnaces possesses the advantages of fast heating (20-40mins) , energy saving, high accuracy of controlling the temperature, reliable heat keeping , auto heating and cooling by programming and a furnace temperature nearing to the indoor. It is widely used in the laboratory and manufacture of the field of pottery, chemical industry, metallurgy, and glass industries, new material developing, machinery, fire-proof material, architecture, special material and etc. | |||||

| > Add to cart | ||||||

| SiC heating elements Jinyu Silca SiC heating element is a type of non-metal high temperature heating device. These SiC productsare made from fine quality green silicon carbide as its main raw material. The raw material is made first in to a blank, followed by high temperature silication and recrystallization, and becomes high quality stick shaped SiC electric heating devicespared with metal electric heating material, this type of non-metal elements is featured of high operation temperature, anti-oxidization, long service life, little deformation, easy installation and maintenance. Because of these advantages, SiC electric heating elements is widely used in various industries that require high temperature electric furnaces and heating devices. These typical applications include electronics, magnetic materials, powder metallurgy, ceramics, glass, metallurgy and machinery. We adopt new production process of cold end, so Jinyu Silca heating elements have excellent specific rate of heat zone resistance and cold end resistance, saving energy, long life, avoiding over-temperature of cold ends damaging furnace body. Products specification: Rod type, U type, W type (Three Phase type), Solid Rod type, Spiral type, 5 piece type (dual hot zone). Sizes are available from Dia 12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm, 31.7mm (1.25inch), 35mm, 38.1mm (1.5 inch), 40mm, 44.4mm (1.75 inch) to 54mm (2.125 inch) for all types. Login to trade with me. Contact: Mr. Amos Guo | |||||

| > Add to cart | ||||||

| silicon carbide SiC heater Jinyu Silca SiC heating element is a type of non-metal high temperature heating device. These SiC productsare made from fine quality green silicon carbide as its main raw material. The raw material is made first in to a blank, followed by high temperature silication and recrystallization, and becomes high quality stick shaped SiC electric heating devicespared with metal electric heating material, this type of non-metal elements is featured of high operation temperature, anti-oxidization, long service life, little deformation, easy installation and maintenance. Because of these advantages, SiC electric heating elements is widely used in various industries that require high temperature electric furnaces and heating devices. These typical applications include electronics, magnetic materials, powder metallurgy, ceramics, glass, metallurgy and machinery. We adopt new production process of cold end, so Jinyu Silca heating elements have excellent specific rate of heat zone resistance and cold end resistance, saving energy, long life, avoiding over-temperature of cold ends damaging furnace body. Products specification: Rod type, U type, W type (Three Phase type), Solid Rod type, Spiral type, 5 piece type (dual hot zone). Sizes are available from Dia 12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm, 31.7mm (1.25inch), 35mm, 38.1mm (1.5 inch), 40mm, 44.4mm (1.75 inch) to 54mm (2.125 inch) for all types. Login to trade with me. Contact: Mr. Amos Guo | |||||

| > Add to cart | ||||||

| tube furnace The high temperature muffle / tube furnace used MoSi2 rods as heating element. Max. temperature inside furnace can be reached at 1650 degree. The furnace temperature profile can be set up by 30 segments and run automatically by the 708 type temperature controller. It is excellent for material research, industry, ceramic research labs. Login to contact me. contact person: Mr Amos Guo. The furnaces possesses the advantages of fast heating (20-40mins) , energy saving, high accuracy of controlling the temperature, reliable heat keeping , auto heating and cooling by programming and a furnace temperature nearing to the indoor. It is widely used in the laboratory and manufacture of the field of pottery, chemical industry, metallurgy, and glass industries, new material developing, machinery, fire-proof material, architecture, special material and etc | |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2026 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||