|

| < Back | ||||||

| Ningbo Gaote Sealing Co.,LTD | ||||||

| About this company : Ningbo Gaote Sealing Elements Co., Ltd. is an enterprise professionally engaging in developing, producing, and selling of sealing elements. It is equipped with advanced producing and inspecting assembly lines and completed managing systems. Our enterprise, depending on the managing principle of “Win by quality, and establish enterprise by morality”, has brought in more completed technologies. Engineers of our company will provide you with the omnidirectional technical services. Possessing reasonable and plenty of inventory, and well-trained quality insurance and logistics teams. Our Principle: Taking man as the end, Exploitation and Innovation! Our Goal: To altogether create a green homeland! Main managing products: Gasket: Metal Spiral Wound Gasket, Metal Toothed Gasket, High-strength Gasket, Metal Jacketed Gasket, Metal Waveform Gasket, Metal Ring Medal, Metal O-Ring Gasket, PTFE Sandwiched and Jacketed Gasket, Cylinder Gasket, Insulation Suite and Expanded PTFE Belt, Graphite Sealing Belt, Rubber Sealing Belt Packing: Aramid Fiber Packing, Carbon Fiber Packing, PTFE Packing, Graphite Packing, Synthetic Fiber Packing, Glass Fiber Packing, Ceramic Fiber Packing, Asbestos Fiber Sheet: Graphite Sheet, PTFE Sheet, Non-asbestos Sheet, Asbestos Rubber Sheet | ||||||

| Contact : Michelle Lv, sales | ||||||

| Headquarters : Rm1411,Xiangge Mansion, Cixi Ningbo, Zhejiang, 315300, China | ||||||

| Phone : 86-574-63925059, Fax : 86-574-63925069 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

| graphite sheet gaote It is made of pure graphite sheet / coiled material, and chemical and high temperature treated by natural high pure flake graphite, and die-pressed or rolling pressed, with no bonding adhesive. Under the harsh working condition, it will still have a good sealing performance, with long lifespan, and low maintain cost. Product application: It can be used to make graphite packing and kinds of half finished products of gasket. Widely used in chemical, automobile, pump and valve industry The graphite, as a new generation of asbestos product, will continuously discover more and more in new applications. Service range: Temperature: -240~450°C oxidative environment -240~3500°C non-oxidative environment PH Value: 0 - 14 Main Index: Index item Industrial level Density tolerance g/cm3 ±0.06 Carbon content ≥% 98 Tensile strength Mpa 4 Compressibility ≥% 30 Recovery ≥% 15 Sulfur content ≤% 1000 Chlorine content ≤% 50 Stress relaxation % 10 Loss on ignition ≤% 2.0 Supplying form: item Sheet Coiled material Density g/cm3 1.0 1.0 or 0.7 Length 1000, 1500mm 30~100m Width mm 1000, 1500 1000~1500 Thickness mm 0.5~3 0.2~1.0 The special density, thickness, size or grade, please notify. | |||||

| > Add to cart | ||||||

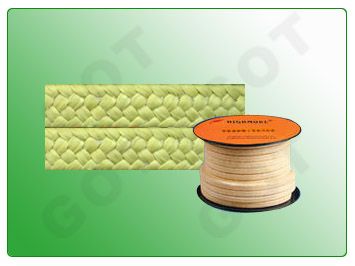

| aramid fiber packing gaote The high quality Du Pont Aramid Fiber dips PTFE emulsion and lubricating additives. The most outstanding performance is high strength, meanwhile a relatively good chemical resistance, high resilience, low cold flow. Although it is quite wearing resistant, used improperly, it will wear out the pump shaft, so we recommend the surface hardness pf the pump shaft and the protection sleeve reaching 60HRC. This packing is inner dipped the mixture mainly silicone oil, it is easy to assembly-disassembly fast and conveniently. Product application: It is a universal type packing, which is widely used in various industry areas, e.g. chemical, refinery, medical, food, sugar making, paper making and electric power, etc. this packing is durable, suitable for wear medium containing solid particles, recommended using for overheat steam, solvent, alcohol vapor, syrup and other wear fluid. It can be used for 160°C hot water under coolant-free circumstance. It can be singly used, or combine with other packing, put in the two ends, as an extrusion-proof ring. Service range: Rotary pump Reciprocating pump Static Sealing Pressure 25 bar 100 bar 200 bar Rotary speed 25 m/s 1.5 m/s Temperature - 100~+280°C PH Value 2~12 Density About 1.4g/cm3 Packaging: 5 or 10kg each coil, other weight on require; according to the length; Making packing | |||||

| > Add to cart | ||||||

| asbestos rubber sheet gaote GOT Asbestos Rubber Sheet is made from selected asbestos fiber, natural rubber, filling material and dye. A price worthy quality of dependable performance, in addition, being suited to many sealing requirements makes this jointing the most economical sheet packing choice in the wide range of industrial fields. Service range: Item style 680 680-1 680-2 680-3 Tensile strength ≥ Mpa 9 12 15 19 Aging coefficient 0.9 0.9 0.9 0.9 Loss on ignition ≤ % 30 30 28 28 Compressibility ≥ % 12±5 12±5 12±5 12±5 Recovery ≥ % 40 40 45 45 Density g/cm3 g/cm3 1.6~2.0 Tmax: 0C 200 300 400 450 Pmax: Mpa 2.3 3.5 5.0 6.0 Resistance to media The jointing parts of equipments and pipelines and flanges using water, steam, diluted acid & alkali, etc. as the medium, under the responding grade temperature and pressure. Lower Grade on request Available color: Purple, red, black, grey etc. Available with inner lined iron wire mesh, copper wire mesh, or 316.304 steel wire mesh, etc. Also available with graphite coating or anti-stick With single face your logo on request Normal dimension: Thickness: 0.4~5mm 2000×1500mm; 1500×4000mm; 1500×1500mm;1350x1500mm 1500×1000mm;1270×1270mm; 3810×1270mm 3810×2700mm (New) | |||||

| > Add to cart | ||||||

| double jacketed gasket gaote GOT Double Jacketed Gasket uses flexible graphite, ceramic fiber, asbestos sheet, and non-asbestos sheet as the filler, jacketed by stainless steel, tinplate, and red copper, etc. kinds of metal thin sheet, which is particularly suitable for high temperature high pressure sealing parts as heat exchanger, and pressure container. It can effectively avoid the gasket from out of shape, and the medium from corrosion, meanwhile it improves pressure resistance. Metal Jacketed Gasket Waveform Jacketed Gasket Other Form Jacketed Gasket Product application: GOT is particularly suitable for heat exchanger, gas pipeline, cast iron flange, cylinder head and boiler, and other containers. Generally, when installed, it can press the initial thickness of the gasket to get a 30% deformation, thus can effectively seal the unevenness and small defects of the flange. Through choosing different metal and different fillers, it can suit to different mediums. Selectable Material: Metal material German Trademark Hardness HB Temperature (℃) Density g/cm3 Carbon Steel, Tinplate 1.1003/1.0038 90~120 -60~500 7.85 SS304, SS304L 1.4301/1.4306 130~180 -250~550 7.9 SS316, SS316L 1.4401/1.4404 130~180 -250~550 7.9 Copper 2.0090 50~80 -250~400 8.9 Aluminum 3.0255 20~30 -250~300 2.73 Other special material e.g. Titanium, Ni, and MONEL, etc. on require Lining material: Flexible graphite, asbestos plate, non-asbestos plate; Ceramic fiber, mica plate, high strength sheet, etc Available size: External diameter: 5000mm Thickness: 2 ~8mm Metal Spiral Wound Gasket | |||||

| > Add to cart | ||||||

| graphite packing gaote It is braided from low sulfur expanded graphite yarns, which are reinforced by inner lining cotton yarn. It has an extremely low friction coefficient, will not damage the shafts and stems, having good thermal conductivity, chemical resistance and high elasticity. Other reinforcement materials are also available: Glass Fiber—high strength, low cost; Carbon Fiber—low loss on ignition. Product structure: Other reinforcement materials are also available: Glass Fiber-------high strength, low cost; Carbon Fiber-------low loss on ignition Product application: GOT-560 can satisfy kinds of sealing demands of the factory, which is widely used in hydrogenation unit, papermaking industry, power station, refinery, which are all under high temperature and high pressure condition, and other valve, pump, expanded joint, mixer, and agitator, etc., which need high effective sealing. Notes: It can’t be used for strong oxidative medium. Suggestion: When used as the filler, it’s better to add GOT-572 high carbon packing end ring, to prevent extrusion. Service range: Rotary pump Reciprocating pump Valve Pressure 20 Bar 100Bar 300Bar- Rotational speed 20m/s 2m/s 2m/s Density 1.0~1.3g/cm3 (+3% -- CAZ 240K) Tempreture -220~+550°C (+650°C --steam) PH value 0~14 Packaging: 5 or 10kg each coil, other weight on require; according to the length; Making packing | |||||

| > Add to cart | ||||||

.jpg) | graphite padding ring gaote Materials: expanded graphite and stainless steel Main purpose: sealing and providing paddings for machine pump and valve. With various capabilities for perfect seal material, can use separately or use with other stuffings, especially applicable for static sealed parts under high temperature, high pressure. | |||||

| > Add to cart | ||||||

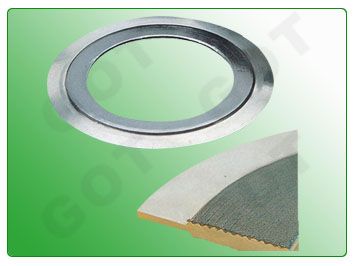

| kammprofile gasket gaote GOT Kammprofile gasket , generally processed to be concentric groove in the two faces of the stainless steel flat gasket by precise lathes. According to the different medium, w can choose flexible graphite, PTFE, non-asbestos, or other soft metal, to sick to the two faces of the gasket. It can directly be used without sealing layer, and the effect is good. But under the high pressure occasion, it will be easy to do damage to the surface of the flange. 410 basic type Kammprofile gasket 410L Kammprofile gasket with outer ring (integral type) 410LM Kammprofile gasket with outer ring (split type) Model 410LM split type Metal toothed gasket with outer ring, can choose richer metal, e.g. carbon steel, as the outer ring, and the outer ring thickness can be 1.5mm, more flexible and economic than the integral type 410L, and the lining metal can be repeatedly used. Product application: GOT toothed combination gasket is the first choice gasket under relatively low preload power, the soft surface of the sealing layer can avoid the direct touch between metal and metal, which is combined reliably and compactly, to protect the metal flange from damaged, even under extremely high load. The toothed combination gasket is especially suitable for the flange connection in thermal exchanger, container, and reaction vessel under high temperature, high pressure, and the working condition altering occasions. It is an ideal substitution for traditional metal jacketed gasket. Operating pressure range: 6.4~25Mpa Selectable material: Metal material German trademark Hardness Temperature ℃ Density g/cm3 Thichness mm Carbon Steel 1.1003/1.0038 90~120 -60~500 7.85 2 3 4 SS304, SS304L 1.4301/1.4306 130~180 -250~550 7.9 SS316, SS316L 1.4401/1.4404 130~180 -250~550 7.9 Other metal on require Overlaying material: Flexible graphite, asbestos plate, non-asbestos plate; PTFE, mica plate, lead, etc. Generally the thickness of the dual overlaying is 0.5mm | |||||

| > Add to cart | ||||||

| non asbestos sheet gaote GOT-630 non-asbestos sheet is made from high-performance synthetic fiber, natural rubber, filling material and dye, compressed and calendered under high temperature and pressure into a sheet form. It is an ideal substitute product for asbestos rubber sheet. Service range: item style 630 630-1 630-2 Density g/cm3 1.8~2.0 1.8~2.0 1.8~2.0 Tensile strength≥Mpa 6 9 12.5 Compressibility ≥% 12±5 12±5 12±5 Recovery ≥% 40 45 45 Aging coefficient 0.9 0.9 0.9 Stress relaxation ≤% 45 45 45 Steam Sealing Tmax: 200℃ Pmax: 2~3Mpa 30min no leakage Tmax: 300℃ Pmax: 4~5Mpa 30min no leakage Tmax: 400℃ Pmax: 8~9Mpa 30min no leakage Tmax: ℃ 200 300 400 Pmax: Mpa 1.5 3.0 5.0 Resistance to media Water, steam, and salt solutions, etc. Normal color: Black, Red, Green-white, Blue, etc. Available with inner lined iron wire mesh, copper wire mesh, or 304 steel wire mesh (43*M) Also available with graphite coating (43*G) or anti-stick(43*S) With single face your logo on request. Available dimension: Thickness: 0.4~5mm 2000×1500mm; 1500×4000mm; 1500×1500mm; 1350x1500mm 1500×1000mm;1270×1270mm; 3810×1270mm | |||||

| > Add to cart | ||||||

| PTFE sheet gaote GOT PTFE products include PTFE Sheet, tube (TU450), rod (RO450), film (FI450), and gasket, etc. It is die-pressed or turned by 100% pure PTFE raw material. In the known plastics, the PTFE has a best corrosion resistance, no aging, low friction coefficient, wearing resistant, and can be safely used between -180~+260C temperature range. Product structure: GOT PTFE products include PTFE Sheet, tube (TU450), rod (RO450), film (FI450), and gasket, etc. It is die-pressed or turned by 100% pure PTFE raw material. In the known plastics, the PTFE has a best corrosion resistance, no aging, low friction coefficient, wearing resistant, and can be safely used between -180~+260C temperature range. The Modified PTFE Sheet is made from the original PTFE powder material by uniformly adding glass fiber, carbon fiber, graphite, and copper, etc., then die-pressedparing with the pure PTFE product, it has better compressive strength, wearing resistance, good thermal conductivity, and low thermal expansion. Service range: Products Tensile strength Pressure Mpa Density g/cm3 Temperature ℃ 650 Pure PTFE Sheet 15Mpa 10 2.1~2.3 -100 ~ 250 650F Modified PTFE Sheet 10Mpa 16 2.1~2.3 -100 ~ 260 EX650 Expanded PTFE Sheet Gore, Klinger, Garlock, Sealon, according to the index of the manufacturer Sealing material,electrical insulation parts,liner,and lubricating guide, etc. Available dimension: Dimension (mm) Thickness (mm) Tolerance 150X150 1.0~30 ±0.30~±0.50 250X250 1.5~30 ±0.30~±0.50 300X300 1.5~30 ±0.30~±0.50 450X450 1.5~30 ±0.30~±0.50 600X600 1.5~30 ±0.30~±0.50 800X800 1.5~30 ±0.30~±0.50 1000X1000 1.5~30 ±0.30~±0.50 1200X1200 2~30 ±0.30~±0.50 1000X2000 3~35 ±0.30~±0.60 1500 X 1500 3~35 ±0.30~±0.60 2000 X 2000 5~35 ±0.30~±0.60 | |||||

| > Add to cart | ||||||

| reinforced graphite gasket gaote It is cut or punched by pure graphite sheet or metal (truss plate, flat plate, net) reinforced graphite sheet, with mass of excellent sealing performance, e.g.: thermal stability, self-lubricating, no aging, non-fragility, etc. Under extreme conditions, it can be stably and long-term used, extremely needing no maintenance. The lining material can choose different metal thin sheet. The model can choose without tipping, inner tipping, outer tipping, and inner-outer tipping. Service range: It can be cut into gaskets in kinds of shapes, which is widely used for the container, boiler, pipeline, and pump, valve and flange, in petrochemical and mining industry, suitable for steam, mineral oil, transformer oil, hydraulic oil, fuel, water, and sea water, etc. Type 430 Compressibility 15~35% Recovery ≥20% Pressure 300bar Graphite Density g/cm3 1.0 Operating Temperature 0C -240~550 PH Value 0~14 Graphite Grade: Item Density Tolerance C≥% Tensile Strength Sulfur Content Chlorine Content Stress Relaxation Loss on Ignition Industrial grade ±0.06 g/cm3 98 4 Mpa <1000ppm <50ppm 10% 2.0≤% | |||||

| > Add to cart | ||||||

| ring joint gasket gaote GOT-450 Ring Joint Gasket chooses solid metal with kinds of materials, and is mechanically cut and processed into metal sealing gaskets with kinds of forms by high precision NC lathe. It is suitable for the sealing part of pressure container, valve, and cylinder head with high temperature, high pressure, and strong corrosion. General characteristic is installation area small and preload pressure high. Metal Flat Gasket Metal Elliptic Gasket Metal Aniseed Gasket RX Type Metal gasket BX Type Metal Gasket Special-shaped Metal Gasket Selectable material: Material Hardness(HB) Temperature(℃) Soft iron 90 530 Carbon steel 120 530 304(L)、321、316(L) 160 750 5Cr1/2Mo 130 500 Relavant standards: Ring Gasket Standards and Flange Standards RJG type RJG Standard Flange Standard R ASME B 16.20,API 6A ANSI B 16.5,ANSI B 16.47 A RX ASME B 16.20,API 6A API 6B BX API 6A API 6BX | |||||

| > Add to cart | ||||||

| spiral wound gasket gaote GOT-400 Spiral Wound Gasket is accumulated, hovered and wound, and spot welded beginning and end terminal by V-shaped or W-shaped stainless steel and non metal filler, which has good compression elasticity, and is suitable for the sealing parts with temperature and pressure altering violently. It is a static sealing parts used for such flange connecting joints as pipeline, valve, bump, heat exchanger, tower, manhole, and hand hole, etc. It is widely applied in departments as petrochemical, mechanical, electric power, metallurgy, boat building, medical, atomic energy, and aerospace, etc. Product standard: We can produce according to standards as ANSI B 16.20,MSS SP-44,API 605,DIN,JIS,JPI,BS 1560,JG/T,GB/T,HG,SH, etc. Or the demands can be designated in detail by clients. E.g. the gasket used for heat exchanger and with ribs, please provide the detailed drawings. Gasket type: Product name Code Suitable for Expression example Basic type metal spiral wound gasket 400 A Tenon slot surface 304/PTFE Metal spiral wound gasket with inner ring 400 B Male-and-female face 304 304/FG Metal spiral wound gasket with outer ring 400 C Convex surface 304/ASB CS Metal spiral wound gasket with inner and outer ring 400 D 304 304/FG CS Metal spiral wound gasket with heat exchanger 400 T Heat exchanger 304/FG with one rib Special-shaped metal spiral wound gasket 400 S Special-shaped Elliptic If the gasket is used for heat exchanger, generally we recommend the one with φ3.2mm stainless steel inner ring. The narrow-band form is divided into sticking type and covering type Selectable material: Steel belt and the inner and outer ring profile Filler General thickness mm Name Code Name Code Appropriate Temperature ℃ V-shape Gasket / Ring W-shape Gasket / Ring Carbon steel CS Asbestos ASB 500 3.2/2.0 4.5/3.0 4.8/3.0 5.5/4.0 7.5/5.0 Stainless steel 304(L),316(L) Graphite FG 650 MONEL Mon PTFE PTFE 250 Ni, Ti Ni,Ti Mica MICA 950 Inconel INC Ceramic CER 1000 Hastelloy, Zr HAST,ZIRC Non-asbestos NAF 300 Generally the material of the inner ring is steel belt, to satisfy the medium and the working condition demands, The outer ring material is the same as the pipe and the related equipment shell, the carbon steel outer ring is relatively economic. The detailed order should indicate the detailed material, the used standard, the inside exhaust pipe nominal diameter DN, the pressure grade PN, or indicate the detailed size: D1:inner diameter of the inner ring;D2: outer diameter of the inner ring; D3:inner diameter of the outer ring;D4: outer diameter of the outer ring Writing methods:D1×D2×D3×D4 The default thickness of the gasket is 4.5mm,and the ring 3mm | |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2025 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||