|

| < Back | ||||||

| Canaan Valve, Pharma Equipment nad trading Group | ||||||

| About this company : CANAAN Technology Group is a regional-free enterprise group composed of Canaan Technology group Co., Ltd., Canaan Technology Group Shanghai Electronics Co., Ltd., Shanghai Canaan Health Food Co., Ltd, Zhejiang Canaan Valve Co., Ltd., Yongjia Fangzheng Valve Electric Co., Ltd., and Yongjia Guoli Clinch Nail Company. The scope of its business covers pharma equipment, chemical equipment, valve, electric and electronic appliance, auto parts, IT, medicine, health food, etc. The company has been awarded as the titles of “ Zhejiang high-tech Enterprise” , “Zhejiang technical innovation outstanding enterprise” “The top 30 enterprise in hometown of pump and valve in China” “ Yongjia leading enterprise”, “Large taxpayer”, “The AAA level bank prestige enterprise ". and “the AAA level tax prestige enterprise”. Zhejiang CANAAN Valve Co., Ltd is the subsidiary of CANAAN Technology Group. Established in 1978, it is one of the earliest valve manufacturers in “Hometown of Pump and Valve in China”. After nearly 30 years of unremitting efforts, it is well-known home and abroad about our electric, manual, gearing, pneumatic, pneumatic-manual and hydraulic transmission valves-- gate valves,globe valves, butterfly valves, ball valve, check valves and the high temperature high pressure power station valves. The company, with land area of 9,500m2 and building area of 15,000 m2, has variety of processing equipments and test equipments. Now, we have 300 staffs, among which there are over 20 intermediate-advanced engineers and technicians. At the same time, owning to the powerful technique, advanced test equipment, good management structure, and quality management process of product design, processing technic development, inspection, processing &assembling and function test, we have first attained ISO9001 quality management system certificate in line and supplied high quality products for Power Station, metallurgy, petrifaction industries. Zhejiang CANAAN Valve Co., Ltd has consistently stuck to the quality policy of "technic innovation to unit with the world, continuous improvement to satisfy the customers”. Meanwhile, we have always adhered to idea of “striving for survival on the basis of quality, development relying on credit standing” to develop new products, extend the field of service and promote the value of customers. | ||||||

| Contact : Francois Fang, Sales Manager | ||||||

| Headquarters : Dong Ou Industrial Zone, Wenzhou, Zhejiang, 325105, China | ||||||

| Phone : 008657767378836, Fax : 008657767378805 | ||||||

| Website : Log on to trade instantly , Email : Log on to trade instantly | ||||||

| Cast steel Gate Valve Cast steel gate valve are designed and manufactured to provide maximum service life and dependability. All gate valves are full ported and meet the design requirements of API STD API600& API6D, BS1414 & BS EN 1984 and generally conform to ASME B16.34. valves are available in a complete range of body/bonnet materials and trim. Materials: Std body/bonnet materials include nine grades of carbon, low alloy and stainless steels. For special applications they can be supplied in other grades of alloy and stainless steel. There’s a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions. DN50 to DN900, Class 150lbs to 1500lbs | |||||

| > Add to cart | ||||||

| all welded stem extension pipeline ball valve PRODUCT SPECIFICATIONS Design Spec API 6D Face to Face API 6D Flange End ASME B16.5,DIN,JIS,etc. Test & Check API 6D Pressure-Temp ASME B16.34 Weld EndsASME B16.25 Marking MSS SP-25 DN50 to DN1400, PN1.6MPa to PN25MPa, Working Temperature: -46℃~150℃ Materials: Design Standard: A350 LF2, A322 4140+ENP, A350 LF2+ENP Cryogenic design: A350 LF2-M, A322 4140+ENP, A350 LF2+ENP Seat : VITON, RPTFE/NYLON/DEVLON/PEEK APPLICATION AREAS All welded underground stem-extension pipeline ball valve is mainly used in petroleum and gas industries. The anti-sulphur series are specially used for natural gas pipeline which contains hydrogen sulphide medium, a lot of impurities and corrosive substances. | ||||||

| > Add to cart | ||||||

.jpg) | ALL-WELDED PIPELINE BALL VALVE CNB-G CNB-G series forged welded ball valve with high performance and new pattern provide many strongpoints: simple and more compact design, lighter and stronger construction, and easier operation. Every ball valve of this series is fire-safe and maintenance free. They are highly recommended to pipeline contractors who require highly reliable, cost-efficient equipment with a long, trouble-free service life. It is the ideal product for every pipe line contractors or providers. PRODUCT SPECIFICATIONS Design Spec API 6D Face to Face API 6D Flange End ASME B16.5,DIN,JIS,etc. Test & Check API 6D Pressure-Temp ASME B16.34 Weld EndsASME B16.25 Marking MSS SP-25 DN50 to DN1400, PN1.6MPa to PN25MPa, Working Temperature: -46℃~150℃ Materials: Design Standard: A350 LF2, A322 4140+ENP, A350 LF2+ENP Cryogenic design: A350 LF2-M, A322 4140+ENP, A350 LF2+ENP Seat : VITON, RPTFE/NYLON/DEVLON/PEEK | |||||

| > Add to cart | ||||||

.jpg) | BALL VALVE 3 WAYS 4WAYS Material ASTM A216-WCB , CF8, CF8M PTFE, PPL SS304 A182 F6a DN50 to DN1200, PN 1.6MPa to 4.0 MPa Applicable temperature -28 ~350℃ Flange end ANSI B16.5、DIN、JIS etc.. Test & inspection API598 Purpose There are T shaped and L shaped Three way ball valves. T shaped ball valve can make the three port orthogonal connect and cut the third passage, thus to realize the function of diversion and combination. L shaped ball valve only connects the two passages which are quartered, it can’t connect the third passage at the same time, it only plays the role of distribution. Structural features Three-way ball valve adopt one-piece structure, with sealing type of four seats, little flanged connection, high reliability and light-duty design. Purpose Four-way ball valve, also named bi-directional four ways conversion valve in power station system. They are applied to the circulatory system of liquid, gas, dust or slurry with solid granules, for example, positive and negative water supply cycle system of condenser in power station unit. This installation occupied large room, high cost, hard operation (as the worker should operate four valves when he switches). On positive water supply ,we open valve 1 and 3, close valve 2 and 4;On reverse water supply, open valve 2 and 4, close valve 1 and 3. We use the four-way ball valve to substitute this operational principle of combination and valve group, which has easy procedure, convenient operation, cost reduction, easy control and good synchronization. Executive standard 1. Design standard APl608 2. Test & Check; API 598 | |||||

| > Add to cart | ||||||

.jpg) | Butterfly Valves Butterfly Valve, eccentric, doucle eccentric, triple eccentric, variable eccentric DN50 to DN2000, PN0.25 to PN4.0MPa, Applicable temperature -46C~510C Material Carbon steel, Stainless steel, Chrome- molybdenum-vanadium steel Carbon steel, Stainless steel, Chrome- molybdenum-vanadium steel Stainless steel, Chrome- molybdenum- vanadium steel Stainless steel, PTFE, Hard and soft laminated metal flakes Stainless steel, Stellite, etc, Hard alloy Flexible graphite, PTFE | |||||

| > Add to cart | ||||||

| FORGED STEEL GATE VALVE Main Features 1. Body and bonnet are forged, so the whole body of the valve has a great strength, fine rigidity and no defection. 2. The structure is B.B, OS&Y design, for some special sealing requirements, adopting the W.B, OS&Y design make sure that the connecting part between the body and bonnet has no leaking. 3. The sealing surface is Co hard alloy welded, which is wearing resistant, erosion proof, abrasion proof and has long life span. 4. After the stem has been heat refined and its surface’s been nitrogenized, it is erosion and abrasion resistant. 5. When nominal pressure is15.0MPa~42.0MPa(Class900~2500Lb), pressure seal structure is adopted, the sealing capacity increase proportionally with the pressure, thus realizing a tight sealing. 6. The size and the material of the parts like flange, butt welding should be chosen according to applications and users’ requirements to meet all kinds of situations. Product Specification Design Spec: ASME B16.3, 4API 602 Face to face: ANSI B16.10 Flange end: ANSI B16.5, JIS, DIN, GB Test & Check: API 598 Pressure-Temp: ANSI B16.34 Socket Weld/Butt Weld: ANSIB16.11/B16.25 NPT: ANSI/ASME B1.20.1 Mark: MSS SP-25 Materials: A105 A182 F22 A182 420 A182 F304 A182 F430&410 A182 F304 A182 F6a A182 F304 working temperature: -29Cto550C | |||||

| > Add to cart | ||||||

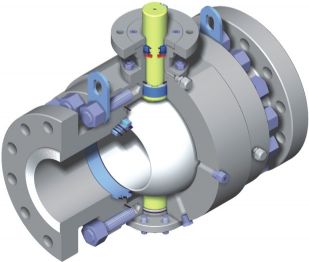

| FORGED STEEL TRUNNION PIPELINE BALL VALVE PRODUCT SPECIFICATIONS Design Spec API 6D Face to Face API 6D Flange End ASME B16.5,DIN,JIS,etc. Test & Check API 6D Pressure-Temp ASME B16.34 Weld EndsASME B16.25 Marking MSS SP-25 DN50 to DN1400, PN1.6MPa to PN25MPa, Working Temperature: -46℃~150℃ Materials: Design Standard: A350 LF2, A322 4140+ENP, A350 LF2+ENP Cryogenic design: A350 LF2-M, A322 4140+ENP, A350 LF2+ENP Seat : VITON, RPTFE/NYLON/DEVLON/PEEK APPLICATION AREAS Forged steel pipeline ball valve is mainly used in petroleum and gas industries. The anti-sulphur series are specially used for natural gas pipeline which contains hydrogen sulphide medium, a lot of impurities and corrosive substances. MAIN FEATURES Forged steel full welded trunnion mounted ball valve adopts forged steel body, after fine machining process; the flange can be bolted connected or welded by auto welder. So, the full body becomes stronger, more rigid and it won’t have any distortion, any leakage and will ensure quality and beauty of the valve for a long time. | |||||

| > Add to cart | ||||||

| Orbital Ball valve Design specifications design reference API Face to face ANSI B16.10 Flange end ANSI B16.5、DIN、JIS butt-welding end MSS SP44、ANSI B16.25 test and check API 598 Materials: A216 WCB A351 CF8/CF8M A352 LCB A217 WC6/WC9 A105+STL A182 F304/316+surface hardening A350 LF2+STL A182 F11/F22+STL Sealing ring : A105+STL A182 F304/316+STL A350 LF2+STL A182 F304+STL NPS2" to NPS24", class 150lbs to 2500lbs, Working Temperature: -29℃~510℃ Structure features 1. Shut on shut off operation without any abrasion: the ball rotates after have separated from the seat, thus this operation eliminates any abrasion of the sealing surface and this way solves the traditional abrasion problem of the ball valves. 2. Torque operation: As there is no friction between seat and ball, it’s very easy for stem operation. Therefore we usually use hand wheel operation for orbital ball valve instead of worm gear operation or others, except big size ball valves. 3. Single-seat design: The static single-seat valve installation can ensure bi-directional zero leakage and that way avoid the problem of cavity pressure increase as in a double-seat valve. 4. Anti-wear hard sealing face: bead welding ball with a layer of hard alloy steel and polished to meet the tough working condition with reliable sealing performance. 5. Self-cleaning: When the ball separates from the seat, the fluid in pipeline will flow through the ball equally along the sphere sealing surface 360 °. This operation doesn’t only eliminate the partial erosion by high-speed fluid on valve seat, but also wash away all the substances accumulated on the sealing surface, then come to purpose of self-cleaning, the way to keep the performance of seal over the time. 6. Top entry type: Top entry ball and seat design, so we can check and maintain without disassembling the body in the line. 7. Seat sealing surface metal protection: Strengthened PTFE is corrugated with metal seat, so that the seat metal sealing surface can get an upstanding protection. 8. Wedge-shaped seal structure: the mechanical force of valve is provided by the stem, it forces the ball on the seat and then keeps it sealed with the body. So the valve sealing performance is not influenced by pipeline pressure. Therefore, it makes the sealing performance reliable in various | |||||

| > Add to cart | ||||||

| Safety Valves High Performance Safety Valve for Steam Service Application CNGS Series High Performance Safety Valve for Steam Service is serviced for overpressure protection of power boiler, once-through boiler,reheater and other pressure vessel and pipe。 900 Series DIN Standard Safety Valve 900 series DIN standard safety valves are mainly applied to trades such as petroleum & burning gas. Due to the super-pressure protecting equipment and precision of action, it is resulted in good recycling function and fast turning back to seat, operating and maintaining convenience. CNNJ Series Safety Valve with Jacket CNXD Series Pilot Operated Safety Valves CNXY Series Pressure Relief Valves | |||||

| > Add to cart | ||||||

| Stainless Steel Sanitary Fittings and Valves Stainless Steel Sanitary Fittings and Valves Materials: Stainless Steel 304, 316L End connections: screwed, flange, butt-welded, quick clamp A large range of models of Butterfly valves (2pieces, 3pieces), Ball Valves (2pieces, 3pieces), Diaphragm valve, Check valves, Sampling valves…DN25 to DN150 A large range of Fittings: sight glasses, clean balls, elbows, equal tee, reducer, cross, U type elbow, hose adapter, plug, gaskets, clamps…NPS: 1" to 4" They’re widely used in Pharmaceutical, chemical and foodstuffs industries. | |||||

| > Add to cart | ||||||

| V-Type Ball Valve Materials: A216 WCB A217 WC6 A351 CF8 A351 CF8M A105 A182 F22 A182 F304 A182 F316 WCB+STL A217 WC6+STL A351 CF8+surface hardening process 1A351 CF8M+ surface hardening process Seat: PTFE/13Cr/CrNi SS+STELLITE DN50 to DN500, PN1.6Mpa, 2.5MPa... Structure Feature 1. There is a shear cut function between the V-shaped cut in ball and the metal seat, especially suitable for impurities like fiber, tiny solid granules, slurry, etc. 2. V Shaped cut ball valve worm gear operation also has the ability of adjusting and location with flow rate near 100% and wide range adjusting. 3. We adopt the adjustable seat structure with spring load, so the seat will not block or separate. Thus, the sealing is reliable and with long life span. | |||||

| > Add to cart | ||||||

| 1 |

| Page 1 of 1 |

|

|

|

|

Know-How | Trading Precaution | Phishing Alerts | SOAOnDemand! | VAR 360 | RSS Feed | ||

| Copyright © 2025 MarginUp All Rights Reserved. MarginUp User Agreement and Privacy Policy. |

||